Uhlobo lwe-M Cone Tungsten Carbide Rotary Burr

Uhlobo lwe-M Cone Tungsten Carbide Rotary Burr

● Ukusika: Okukodwa, Okukabili, Idayimane, Ukusika kwe-Alu

● Ukugqoka: Kungagcotshwa nge-TiAlN

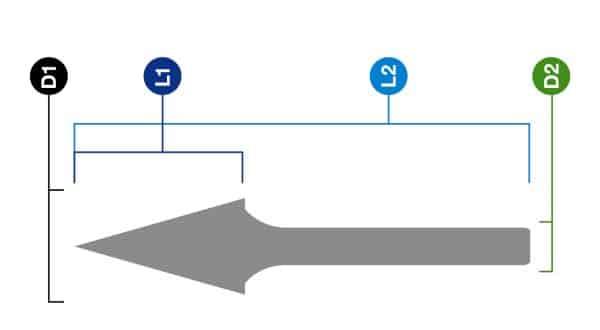

Imethrikhi

| Imodeli | D1 | L1 | L2 | D2 | Sika Single | Sika kabili | I-Diamond Cut | Alu Cut |

| M0307 | 3 | 7 | 40 | 3 | 660-3118 | 660-3124 | 660-3130 | 660-3136 |

| M0311 | 3 | 11 | 40 | 3 | 660-3119 | 660-3125 | 660-3131 | 660-3137 |

| M0613 | 6 | 13 | 43 | 3 | 660-3120 | 660-3126 | 660-3132 | 660-3138 |

| M0618 | 6 | 18 | 50 | 6 | 660-3121 | 660-3127 | 660-3133 | 660-3139 |

| I-M1020 | 10 | 20 | 60 | 6 | 660-3122 | 660-3128 | 660-3134 | 660-3140 |

| M1225 | 12 | 25 | 65 | 6 | 660-3123 | 660-3129 | 660-3135 | 660-3141 |

Intshi

| Imodeli | D1 | L1 | L2 | D2 | Sika Single | Sika kabili | I-Diamond Cut | Alu Cut |

| I-SM-1 | 1/4" | 1/2" | 22º | 1/4" | 660-3554 | 660-3560 | 660-3566 | 660-3572 |

| I-SM-2 | 1/4" | 3/4" | 14º | 1/4" | 660-3555 | 660-3561 | 660-3567 | 660-3573 |

| I-SM-3 | 1/4" | 1" | 10º | 1/4" | 660-3556 | 660-3562 | 660-3568 | 660-3574 |

| I-SM-4 | 3/8" | 5/8" | 28º | 1/4" | 660-3557 | 660-3563 | 660-3569 | 660-3575 |

| I-SM-5 | 1/2" | 7/8" | 28º | 1/4" | 660-3558 | 660-3564 | 660-3570 | 660-3576 |

| I-SM-6 | 5/8" | 1" | 31º | 1/4" | 660-3559 | 660-3565 | 660-3571 | 660-3577 |

Metal Fabrication Deburring

Ama-Tungsten Carbide Rotary Burrs ahlonishwa kakhulu embonini yensimbi ngenxa yokuguquguquka kwawo nokusebenza okukhethekile emisebenzini eminingi. Ukusetshenziswa okuyinhloko kwalawa mathuluzi kuhlanganisa.

I-Deburring and Welding Treatment: Lawa mabhula ahlukile ekwenziweni kwensimbi, asebenza kahle kakhulu ekususeni ama-burrs abangelwa ukushisela noma ukusikwa.

Ukubunjwa Okunembe Nokuqoshwa

Ukuqina kwazo okuphakeme nokumelana nokuguga kuzenza zibe amathuluzi afanele okusebenza okunemininingwane nokunembayo kokukhipha imali.

Ukubunjwa Nokuqoshwa: Yaziwa ngokunemba kwayo ekubumbeni, ekuqopheni, nasekuphunguleni izingxenye zensimbi, i-Tungsten Carbide Rotary Burrs iphumelela kakhulu ekusebenzeni ngezinsimbi ezihlukahlukene, okuhlanganisa kodwa okungagcini nje kuma-alloys aqinile nama-alloys e-aluminium.

Ukugaya kanye Nokupholisha Ngempumelelo

Ukugaya kanye Nokupholisha: Emkhakheni wokusebenza kwensimbi ngokunemba, lawa mabhula abalulekile, ikakhulukazi emisebenzini yokugaya nokupholisha. Ukuqina kwazo okuphawulekayo nokuqina okuhlala isikhathi eside kuthuthukisa ukusebenza kwazo kulezi zindawo.

Ukulungiswa kanye nokuhlela kabusha

I-Reaming and Edging: I-Tungsten Carbide Rotary Burrs imvamisa ingamathuluzi okuzikhethela ukulungisa noma ukuthuthukisa ubukhulu namakhonsana wemigodi ekhona ezinqubweni zokukhiqiza ngomshini.

I-Casting Surface Cleaning

Ukuhlanza Abalingisi: Embonini yokulingisa, lawa ma-burrs adlala indima ebalulekile ekususeni okubalulekile ekulingisini nasekuthuthukiseni ikhwalithi yawo engaphezulu.

Ukuqaliswa kwazo okusabalele ezimbonini ezahlukahlukene, njengokukhiqiza, ukulungisa izimoto, ubuciko bensimbi, kanye ne-aerospace, kugcizelela ukusebenza kahle okuphezulu kanye nemvelo eguquguqukayo ye-Tungsten Carbide Rotary Burrs.

Inzuzo Yokuhamba Ngezindlela

• Inkonzo Ephumelelayo Nethembekile;

• Ikhwalithi Enhle;

• Amanani Okuncintisana;

• OEM, ODM, OBM;

• Izinhlobonhlobo Ezibanzi

• Ukulethwa Okusheshayo Nokwethenjelwa

Okuqukethwe Kwephakheji

1 x Uhlobo lwe-M Cone Tungsten Carbide Rotary Burr

1 x Ikesi Lokuvikela

● Ingabe udinga i-OEM, i-OBM, i-ODM noma ukupakishwa okungathathi hlangothi kwemikhiqizo yakho?

● Igama lenkampani yakho kanye nolwazi lokuxhumana ukuze uthole impendulo esheshayo nenembile.

Ukwengeza, sikumema ukuthi ucele amasampula okuhlolwa kwekhwalithi.