Thayipha i-H Flame Tungsten Carbide Rotary Burr

Thayipha i-H Flame Tungsten Carbide Rotary Burr

● Ukusika: Okukodwa, Okukabili, Idayimane, Ukusika kwe-Alu

● Ukugqoka: Kungagcotshwa nge-TiAlN

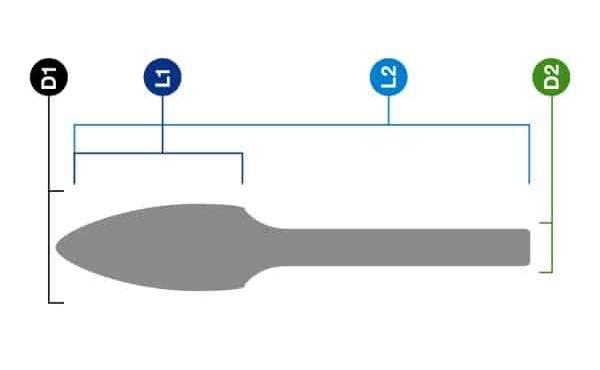

Imethrikhi

| Imodeli | D1 | L1 | L2 | D2 | Sika Single | Sika kabili | I-Diamond Cut | Alu Cut |

| H0307 | 3 | 7 | 40 | 3 | 660-3079 | 660-3083 | 660-3087 | 660-3091 |

| H0613 | 6 | 13 | 43 | 3 | 660-3080 | 660-3084 | 660-3088 | 660-3092 |

| H0820 | 8 | 20 | 60 | 6 | 660-3081 | 660-3085 | 660-3089 | 660-3093 |

| H0230 | 12 | 30 | 70 | 6 | 660-3082 | 660-3086 | 660-3090 | 660-3094 |

Intshi

| Imodeli | D1 | L1 | D2 | Sika Single | Sika kabili | I-Diamond Cut | Alu Cut |

| SH-41 | 1/8" | 1/4" | 1/8" | 660-3498 | 660-3506 | 660-3514 | 660-3522 |

| SH-53 | 3/16" | 3/8" | 1/4" | 660-3499 | 660-3507 | 660-3515 | 660-3523 |

| SH-1 | 1/4" | 5/8" | 1/4" | 660-3500 | 660-3508 | 660-3516 | 660-3524 |

| SH-2 | 5/16" | 3/4" | 1/4" | 660-3501 | 660-3509 | 660-3517 | 660-3525 |

| SH-3 | 3/8" | 1" | 1/4" | 660-3502 | 660-3510 | 660-3518 | 660-3526 |

| SH-5 | 1/2" | 1-1/4" | 1/4" | 660-3503 | 660-3511 | 660-3519 | 660-3527 |

| SH-6 | 5/8" | 1-7/16" | 1/4" | 660-3504 | 660-3512 | 660-3520 | 660-3528 |

| SH-7 | 3/4" | 1-5/8" | 1/4" | 660-3505 | 660-3513 | 660-3521 | 660-3529 |

Metal Fabrication Deburring

Ama-Tungsten Carbide Rotary Burrs ajabulela ukutuswa kabanzi embonini yensimbi, ngenxa yezinhlelo zabo ezihlukahlukene kanye nokusebenza okuvelele kuyo yonke imisebenzi ehlukahlukene. Izindima zabo eziyinhloko zihlanganisa.

I-Deburring and Welding Treatment: Ibalulekile ekwenziweni kwensimbi, lawa ma-burrs ahamba phambili ekuqedeni ama-burrs akhiqizwa ngesikhathi sezinqubo zokushisela noma zokusika. Ukuqina kwazo okuphakeme nokumelana nokugqoka kuzenza zikufanelekele ukuchithwa ngokucophelela

Ukubunjwa Kwensimbi Okunembile kanye nemisebenzi yokuqopha

Ukubunjwa Nokuqoshwa: Idume ngokunemba ekubumbeni, ekuqopheni, nasekusikeni izingxenye zensimbi, iTungsten Carbide Rotary Burrs ikhombisa ubungcweti obukhethekile ngezinhlobonhlobo zezinsimbi, okuhlanganisa ama-alloys aqinile nama-alloys e-aluminium.

Ukugaya Okuthuthukisiwe Nokupholisha

Ukugaya kanye Nokupholisha: Okubalulekile emkhakheni wokunemba kwensimbi, lawa mabhula asebenza kahle kakhulu ekugayeni nasekupholisheni imisebenzi. Ubulukhuni nokuqina kwazo okumangalisayo kuthuthukisa kakhulu ukusebenza kwazo kulezi zinhlelo zokusebenza.

I-Mechanical Manufacturing Reaming

I-Reaming and Edging: Isetshenziselwa kabanzi ukulungisa noma ukulungisa usayizi nokuma kwezimbobo ezikhona ezinqubweni zokukhiqiza ngomshini, i-Tungsten Carbide Rotary Burrs idlala indima ebalulekile.

I-Casting Surface Cleaning

Ukuhlanza Ukusakaza: Embonini yokulingisa, lawa ma-burrs abalulekile ekususeni okubalulekile kokulingisa, okunikela ekuqedeni okuthuthukisiwe kwendawo.

Ukusetshenziswa okusabalele kwe-Tungsten Carbide Rotary Burrs ezimbonini ezahlukahlukene ezinjengokukhiqiza, ukukhanda izimoto, ukwenza insimbi, kanye ne-aerospace kuwubufakazi bokusebenza kwazo okuphezulu nokuzivumelanisa nezimo.

Inzuzo Yokuhamba Ngezindlela

• Inkonzo Ephumelelayo Nethembekile;

• Ikhwalithi Enhle;

• Amanani Okuncintisana;

• OEM, ODM, OBM;

• Izinhlobonhlobo Ezibanzi

• Ukulethwa Okusheshayo Nokwethenjelwa

Okuqukethwe Kwephakheji

1 x Uhlobo H I-Flame Tungsten Carbide Rotary Burr

1 x Ikesi Lokuvikela

● Ingabe udinga i-OEM, i-OBM, i-ODM noma ukupakishwa okungathathi hlangothi kwemikhiqizo yakho?

● Igama lenkampani yakho kanye nolwazi lokuxhumana ukuze uthole impendulo esheshayo nenembile.

Ukwengeza, sikumema ukuthi ucele amasampula okuhlolwa kwekhwalithi.