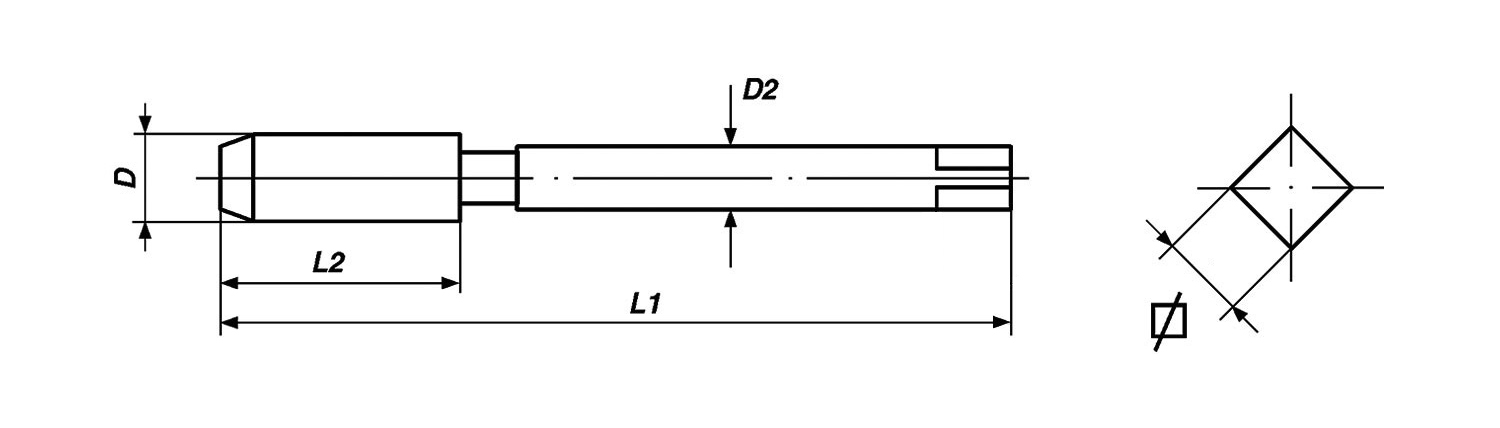

I-HSS DIN371 Threading Tap With Straight And Spiral or Spiral Point Flute

Ukucaciswa

Igama lomkhiqizo: I-DIN371 Machine Tap

I-Engeli yochungechunge: 60°

Umtshingo: Iphuzu eliqondile/ Elivunguzayo/ Umtshingo ovunguza ngokushesha 35º/ Umtshingo ovunguza kancane 15º

Indwangu: HSS/HSCo5%

I-Coating: Bright/TiN/TiCN

Umtshingo Oqondile

| SIZE (D) | UCHWEPHESHE UBUDE(L2) | TOTAL UBUDE(L1) | SHANK I-DIA.(D2) | ISIkwele (a) | HSS | HSSCo5% | ||

| Okugqamile | I-TiN | Okugqamile | I-TiN | |||||

| M2×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3818 | 660-3831 | 660-3857 | 660-3870 |

| M2.3×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3819 | 660-3832 | 660-3858 | 660-3871 |

| M2.5×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3820 | 660-3833 | 660-3859 | 660-3872 |

| M2.6×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3821 | 660-3834 | 660-3860 | 660-3873 |

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-3822 | 660-3835 | 660-3861 | 660-3874 |

| M3.5×0.6 | 12 | 56 | 4 | 3 | 660-3823 | 660-3836 | 660-3862 | 660-3875 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-3824 | 660-3837 | 660-3863 | 660-3876 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-3825 | 660-3838 | 660-3864 | 660-3877 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-3826 | 660-3839 | 660-3865 | 660-3878 |

| M7×1 | 17 | 80 | 7 | 5.5 | 660-3827 | 660-3840 | 660-3866 | 660-3879 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-3828 | 660-3841 | 660-3867 | 660-3880 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-3829 | 660-3842 | 660-3868 | 660-3881 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-3830 | 660-3843 | 660-3869 | 660-3882 |

I-Spiral Point

| SIZE (D) | UCHWEPHESHE UBUDE(L2) | TOTAL UBUDE(L1) | SHANK I-DIA.(D2) | ISIkwele (a) | HSS | HSSCo5% | ||

| Okugqamile | I-TiN | Okugqamile | I-TiN | |||||

| M2×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3896 | 660-3909 | 660-3935 | 660-3948 |

| M2.3×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3897 | 660-3910 | 660-3936 | 660-3949 |

| M2.5×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3898 | 660-3911 | 660-3937 | 660-3950 |

| M2.6×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3899 | 660-3912 | 660-3938 | 660-3951 |

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-3900 | 660-3913 | 660-3939 | 660-3952 |

| M3.5×0.6 | 12 | 56 | 4 | 3 | 660-3901 | 660-3914 | 660-3940 | 660-3953 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-3902 | 660-3915 | 660-3941 | 660-3954 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-3903 | 660-3916 | 660-3942 | 660-3955 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-3904 | 660-3917 | 660-3943 | 660-3956 |

| M7×1 | 17 | 80 | 7 | 5.5 | 660-3905 | 660-3918 | 660-3944 | 660-3957 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-3906 | 660-3919 | 660-3945 | 660-3958 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-3907 | 660-3920 | 660-3946 | 660-3959 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-3908 | 660-3921 | 660-3947 | 660-3960 |

I-Fast Spiral Flute 35º

| SIZE (D) | UCHWEPHESHE UBUDE(L2) | TOTAL UBUDE(L1) | SHANK I-DIA.(D2) | ISIkwele (a) | HSS | HSSCo5% | ||

| Okugqamile | I-TiN | Okugqamile | I-TiN | |||||

| M3×0.5 | 5 | 56 | 3.5 | 2.7 | 660-3974 | 660-3981 | 660-3995 | 660-4002 |

| M4×0.7 | 7 | 63 | 4.5 | 3.4 | 660-3975 | 660-3982 | 660-3996 | 660-4003 |

| M5×0.8 | 8 | 70 | 6 | 4.9 | 660-3976 | 660-3983 | 660-3997 | 660-4004 |

| M6×1 | 10 | 80 | 6 | 4.9 | 660-3977 | 660-3984 | 660-3998 | 660-4005 |

| M8×1.25 | 13 | 90 | 8 | 6.2 | 660-3978 | 660-3985 | 660-3999 | 660-4006 |

| M10×1.5 | 15 | 100 | 10 | 8 | 660-3979 | 660-3986 | 660-4000 | 660-4007 |

| M12×1.75 | 18 | 110 | 12 | 9 | 660-3980 | 660-3987 | 660-4001 | 660-4008 |

I-Slow Spiral Flute 15º

| SIZE (D) | UCHWEPHESHE UBUDE(L2) | TOTAL UBUDE(L1) | SHANK I-DIA.(D2) | ISIkwele (a) | HSS | HSSCo5% | ||

| Okugqamile | I-TiN | Okugqamile | I-TiN | |||||

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-4016 | 660-4023 | 660-4037 | 660-4044 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-4017 | 660-4024 | 660-4038 | 660-4045 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-4018 | 660-4025 | 660-4039 | 660-4046 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-4019 | 660-4026 | 660-4040 | 660-4047 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-4020 | 660-4027 | 660-4041 | 660-4048 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-4021 | 660-4028 | 660-4042 | 660-4049 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-4022 | 660-4029 | 660-4043 | 660-4050 |

I-Sight Flute DIN 371 Machine Tap

Isicelo: Ilungele ukuthunga impumputhe noma ngezimbobo zensimbi, insimbi engagqwali, insimbi ewuketshezi, nezinto ezingezona insimbi. Amazinyo ayo aphansi kanye ne-chamfer emboza imicu emi-2-3 kuyenza ifanelekele ukujula kwentambo okuphindwe izikhathi ezi-2 kunobubanzi bompompi (2d1).

Ukusetshenziswa Okunconyiwe: Lolu hlobo lusebenza kahle kakhulu ekuthepheni ngesandla ngenxa yemitshingo yalo eqondile, enikeza ukuzinza kanye nokusebenziseka kalula.

Spiral Point DIN 371 Machine Tap

Isicelo: Idizayinelwe ukudala imicu emigodini, lokhu kuthepha kuhlanganisa amazinyo aphansi kanye ne-chamfer yemicu emi-4-5. Isebenza kahle ekujuleni kwentambo kufika izikhathi ezi-3 kunodayamitha kampompi (3d1) ngensimbi, insimbi engagqwali, ne-cast iron.

Ukusetshenziswa Okunconyiwe: Iphoyinti elivunguzayo liphushela ama-chips phambili, ikwenze ilungele ukudlula izimbobo lapho ukukhishwa kwe-chip kuqondile.

I-Fast Spiral Flute 35º DIN 371 Machine Tap

Uhlelo lokusebenza: Lo mpompi uklanyelwe izimbobo eziyizimpumputhe zensimbi, insimbi engagqwali, insimbi ecijile, nezinto ezingezona insimbi ezinocu olujulile olufika ku-2.5 ubukhulu bompompi (2.5d1). Umtshingo ovunguzayo ongu-35º usiza ekuphumeni okuphumelelayo kwe-chip.

Ukusetshenziswa Okunconyiwe: Ifanele imishini ye-CNC lapho ukucupha okunesivinini esikhulu nokunemba kubaluleke kakhulu.

I-Slow Spiral Flute 15º DIN 371 Machine Tap

Isicelo: Njengozakwabo ovunguzayo osheshayo, lo mpompi usetshenziselwa izimbobo ezingaboni ezintweni ezifanayo, kodwa ngomkhawulo wokujula kwentambo ophindwe izikhathi ezingu-2 kunobubanzi bompompi (2d1). Umtshingo we-slow spiral 15º unikeza ukususwa kwe-chip okulawulwayo.

Ukusetshenziswa Okunconyiwe: Kunconyelwe izinto ezikhiqiza ama-chips amade, anezintambo, okuqinisekisa inqubo yokuhlanganisa ehlanzekile.

Izinketho zokumboza

Bright, TiN (Titanium Nitride), TiCN (Titanium Carbonitride): Lezi zimbobo zithuthukisa ukuqina kukampompi, ukumelana nokushisa, nokuthambisa, ngaleyo ndlela kwandise ukuphila kwamathuluzi nokusebenza ezintweni ezihlukahlukene.

Ngamunye walawa mampompi angenziwa ngendlela efanele ukuze asetshenziswe ezindaweni ezihlukene zomshini, kuye ngezinto ezibonakalayo, uhlobo lwembobo, nokujula kwentambo oyithandayo. Kubalulekile ukukhetha uhlobo olulungile lokuthepha ngomshini kwe-DIN 371 kuhlelo lokusebenza ngalunye ukuze kuqinisekiswe ukusebenza okuhle nokuphila isikhathi eside kwethuluzi.

Inzuzo Yokuhamba Ngezindlela

• Inkonzo Ephumelelayo Nethembekile;

• Ikhwalithi Enhle;

• Amanani Okuncintisana;

• OEM, ODM, OBM;

• Izinhlobonhlobo Ezibanzi

• Ukulethwa Okusheshayo Nokwethenjelwa

Okuqukethwe Kwephakheji

1 x DIN371 Machine Tap

1 x Ikesi Lokuvikela

● Ingabe udinga i-OEM, i-OBM, i-ODM noma ukupakishwa okungathathi hlangothi kwemikhiqizo yakho?

● Igama lenkampani yakho kanye nolwazi lokuxhumana ukuze uthole impendulo esheshayo nenembile.

Ukwengeza, sikumema ukuthi ucele amasampula okuhlolwa kwekhwalithi.