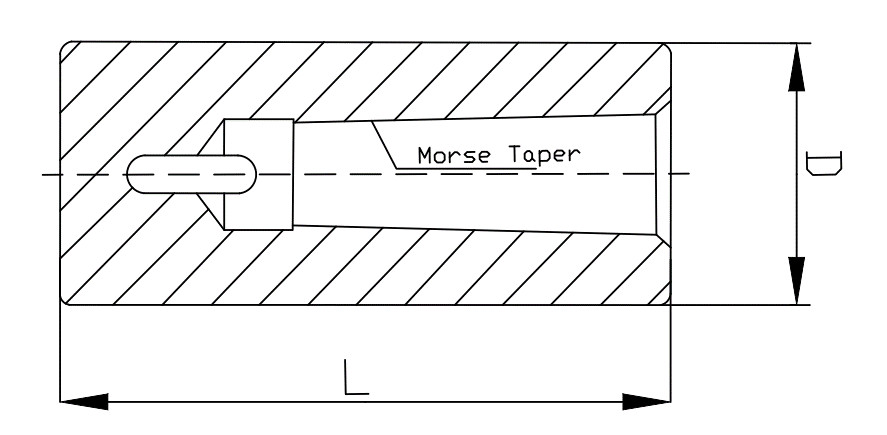

Precision Straight Shank To Morse Taper Adapter

Straight Shank To Morse Taper Adapter

● High-precision morse taper internal diameter.

● accurately straight shank outer diameter for our straight shank to morse taper sleeves.

● A Grade-Made from high-grade Carbon Steel-Completely hardened & precision ground internally & externally for our straight shank to morse taper sleeves.

| Solid Socket Number |

Morse Taper I.D. |

Shank Diameter D |

Overall Length L |

Order No. |

| 1 | 1 | 1” | 3-1/2 | 214-8701 |

| 2 | 1 | 1-1/4” | 3-1/2 | 214-8702 |

| 3 | 1 | 1-1/2” | 3-1/2 | 214-8703 |

| 4 | 2 | 1” | 4 | 214-8704 |

| 5 | 2 | 1-1/4” | 4 | 214-8705 |

| 6 | 2 | 1-1/2” | 4 | 214-8706 |

| 7 | 2 | 1-3/4” | 4 | 214-8707 |

| 8 | 2 | 2” | 4 | 214-8708 |

| 9 | 3 | 1-1/4” | 4-3/4 | 214-8709 |

| 10 | 3 | 1-1/2” | 4-3/4 | 214-8710 |

| 11 | 3 | 1-3/4” | 4-3/4 | 214-8711 |

| 12 | 3 | 2” | 4-3/4 | 214-8712 |

| 13 | 4 | 1-1/2” | 6 | 214-8713 |

| 14 | 4 | 1-3/4” | 6 | 214-8714 |

| 15 | 4 | 2” | 6 | 214-8715 |

| 16 | 5 | 2-1/4” | 7-3/8 | 214-8716 |

| 17 | 5 | 2-1/2” | 7-3/8 | 214-8717 |

| 18 | 6 | 3-1/4” | 10-1/8 | 214-8718 |

| 19 | 6 | 3-1/2” | 10-1/8 | 214-8719 |

Enhancing Tool Compatibility and Precision

The Straight Shank to Morse Taper Adapter is a crucial component in the realm of machine tool machining, bridging the compatibility gap between different tooling interfaces and enhancing the versatility and efficiency of machining operations. This adapter, characterized by its high-precision Morse taper internal diameter, accurately straight shank outer diameter, and construction from high-grade carbon steel that is completely hardened and precision ground both internally and externally, is essential for workshops and manufacturers aiming to maximize the utility of their equipment.

Precision Fit for High-Accuracy Machining

In the domain of machine tool machining, the precision and reliability of tooling components are paramount. The Straight Shank to Morse Taper Adapter fulfills this requirement by providing a seamless and secure connection between tools with straight shanks and machines with Morse taper spindles. This compatibility is vital for workshops that utilize a wide range of equipment, enabling them to adapt various tools to machines with different spindle types without compromising on precision or performance.

Simplified Tool Changes for Operational Efficiency

The high-precision Morse taper internal diameter of the adapter ensures a snug fit, minimizing tool runout and vibration during operation. This precision is critical for tasks that demand high accuracy, such as precision drilling, reaming, and milling in industries like aerospace, automotive, and precision engineering. By reducing tool deflection and ensuring the stability of the tool during machining, the adapter directly contributes to the quality of the final product, reducing scrap rates and improving overall manufacturing efficiency.

Durable Construction for Long-Term Use

Moreover, the accurately straight shank outer diameter of these adapters facilitates a secure and straightforward attachment to tools. This feature simplifies the setup process, allowing for quick tool changes and reducing downtime in fast-paced production environments. The ease of tool change provided by the Straight Shank to Morse Taper Adapter enhances operational efficiency, making it a valuable asset in both high-volume manufacturing and custom, one-off production scenarios.

Versatility Across Machining Operations

Constructed from high-grade carbon steel and subjected to a comprehensive hardening and precision grinding process, the Straight Shank to Morse Taper Adapter is designed for durability and long-term use. This robust construction ensures that the adapter can withstand the rigors of continuous operation, including the high forces and temperatures encountered during metal cutting processes. The durability of the adapter not only ensures consistent performance over time but also reduces the need for frequent replacements, contributing to lower operational costs. The application of the Straight Shank to Morse Taper Adapter extends across various machining operations, from conventional milling and drilling to more specialized applications like jig boring. The versatility provided by the adapter enables workshops to expand the range of operations they can perform with existing machinery, effectively increasing the utility of their equipment. For example, a machine designed primarily for drilling can, with the use of this adapter, also accommodate milling cutters, thereby broadening the scope of projects that can be undertaken. The Straight Shank to Morse Taper Adapter is an indispensable tool in machine tool machining, offering unmatched precision, versatility, and durability. Its application across a broad spectrum of machining operations underscores its value in optimizing the performance and flexibility of machining equipment. By enabling the use of straight shank tools in Morse taper machines, this morse taper adapter plays a pivotal role in enhancing the productivity and efficiency of manufacturing operations, making it a key component in the pursuit of precision and excellence in the machining industry.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Straight Shank To Morse Taper Adapter

1 x Protective Case

Please contact us for further information. To assist you more effectively, Kindly provide the following details:

● Specific product models and the approximate quantities you require.

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.