Precision V Block Set Ka Mofuta oa Boleng bo Phahameng

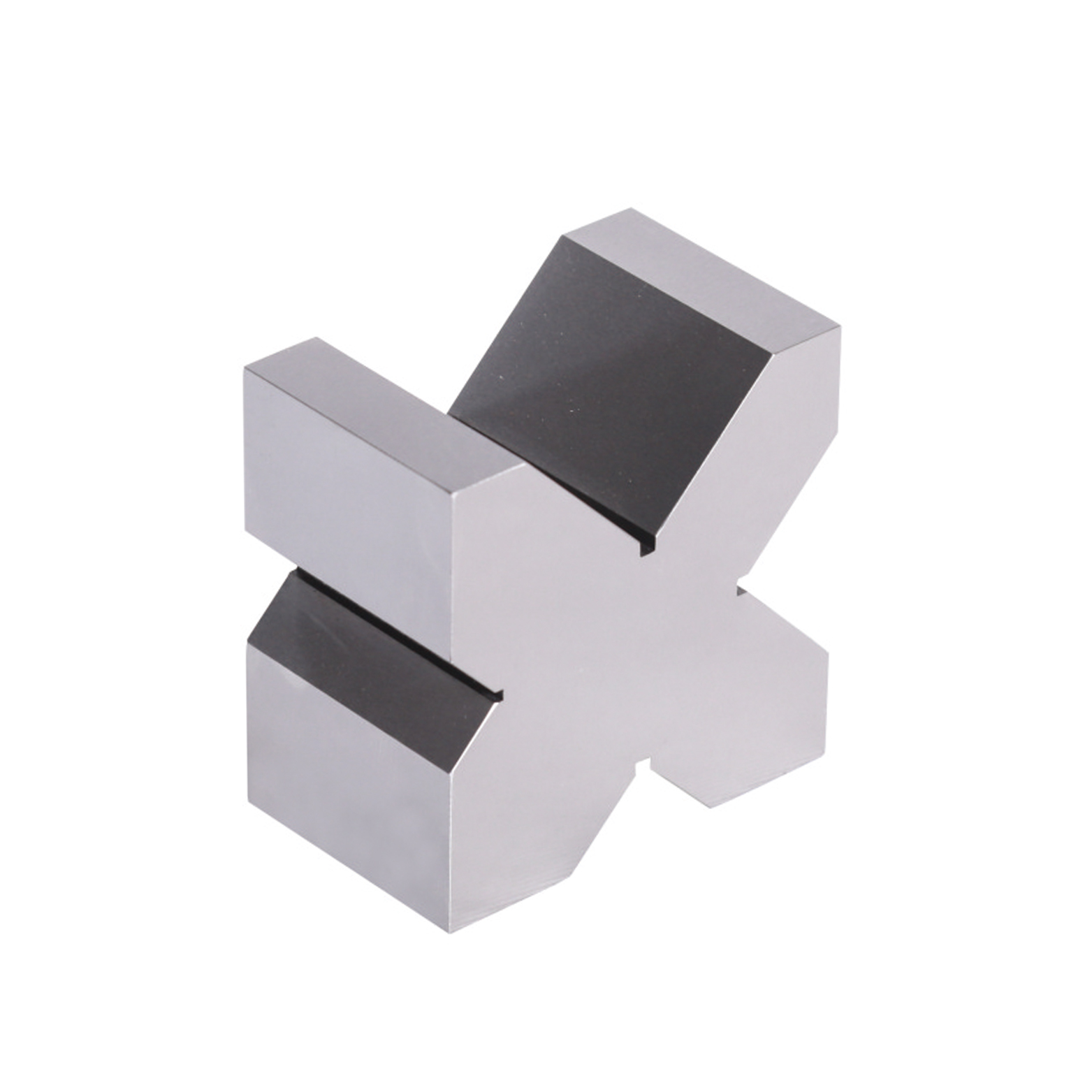

V Block le Clamps Set

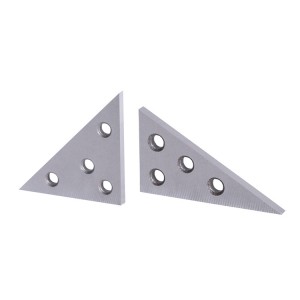

● Hardness HRC: 52-58

● Ho nepahala: 0.01mm

● Sekwere: 0.01mm

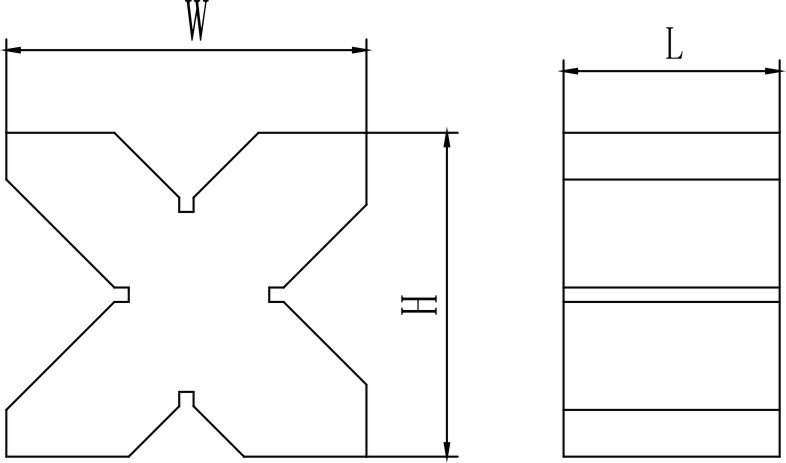

| Boholo(LxWxH) | Clamping Range(mm) | Odara No. |

| 30x38x38mm | 5-20 | 860-1034 |

| 50x80x80mm | 6-50 | 860-1035 |

| 60x100x100mm | 6-68 | 860-1036 |

Ho utulla ho Fetoha ha V Blocks in Precision Workholding

Sebakeng se rarahaneng sa ho sebetsa ka mokhoa o nepahetseng, li-V blocks li eme li le telele joalo ka litšiea tsa motheo, tse nang le bokhoni bo ke keng ba lekanngoa ba ho boloka le ho beha lisebelisoa tsa mosebetsi ka nepo e makatsang. Lisebelisoa tsena tse feto-fetohang li ipaka e le tsa bohlokoa liindastering tse fapaneng moo ho sebetsa ka nepo, ho lekola ka hloko le ho kopanya ka thata e seng lipheo feela empa e le litlhokahalo tse felletseng.

Tsebo ho Machining

Ka har'a sebaka sa ts'ebetso ea machining, V blocks e bapala karolo ea bohlokoa, ho fana ka ts'ehetso e sa thekeseleng nakong ea ho sila, ho cheka le ho sila. Sebaka sa sebopeho sa V ka har'a li-block tsena se theha bethe e tsitsitseng bakeng sa lisebelisoa tsa cylindrical kapa tse chitja, tse nolofalletsang ts'ebetso ea machining ho buleha ka symphony ea ho nepahala le ho pheta-pheta.

Nepahetseng ho Tlhahlobo le Metrology

Ho nepahala ha tlhaho ha li-block tsa V ho li etsa hore e be tsa bohlokoa haholo tlhahlobong le lits'ebetsong tsa metrology. Lisebelisoa tse sirelelitsoeng ka har'a li-block tsa V li hlahlojoa ka hloko ho sebelisoa lisebelisoa tsa ho metha tse nepahetseng. Setupo sena se matlafatsa bahlahlobi ho lekola boholo, li-angles, le concentricity ka boemo ba ho nepahala bo tsamaellanang le mamello e thata.

Bokhabane ho Tool and Die Makeing

Sebakeng sa ho etsa lisebelisoa le ho shoa, moo ho nepahetseng ho leng bohlokoa haholo, li-block tsa V li nka setsi sa bohareng. Lisebelisoa tsena li thusa ho beoa hantle ha li-workpieces nakong ea ho theha le ho netefatsa liforomo tse rarahaneng le ho shoa. Botsitso bo fanoeng ke li-block tsa V bo tiisa hore mekhoa ea machining e fana ka likarolo tse nang le litlhaloso tse hlakileng tsa bohlokoa bakeng sa tlhahiso ea lisebelisoa le lefu.

Precision Unleashed in Welding and Fabrication

Li-V blocks li bapala karolo ea bohlokoa ts'ebetsong ea ho cheselletsa le ho etsa masela. Li-welders li phahamisa li-block tsa V ho tšoara le ho hokahanya likotoana tsa tšepe ka mokhoa o sireletsehileng, ho hlophisa li-welds ka symphony ea ho nepahala. Khatello e tiileng e sebelisitsoeng e tiisa botšepehi ba sebopeho sa kopano e cheselitsoeng, ho netefatsa ho kopanngoa ho se nang moeli ha likarolo.

Kutloano Ts'ebetsong ea Kopano

Nakong ea ts'ebetso ea kopano, li-block tsa V li sebetsa joalo ka li-conductor tse hlophisang tlhophiso e nepahetseng le ho lokisoa ha likarolo. Ebang ke sebakeng sa likoloi kapa sebakeng sa sefofane, lisebelisoa tsena li netefatsa hore likarolo li behiloe ka mokhoa o sireletsehileng sebakeng se nepahetseng, 'me li rala motheo bakeng sa kopano e finyellang litekanyetso tse nepahetseng tsa boleng le litlhoko tsa ts'ebetso.

Thuto e Matlafatsang

Li-V blocks li hlaha e le lisebelisoa tsa bohlokoa tsa thuto, haholo lithutong tsa boenjiniere le tsa machining. Baithuti ba sebelisana le lisebelisoa tsena ho utloisisa melao-motheo ea ts'ebetso, mamello ea jiometri, le tekanyo e nepahetseng. Boiphihlelo ba matsoho bo fumanoeng ka V blocks bo matlafatsa kutloisiso ea baithuti ea menahano ea mantlha ea boenjiniere.

Ho netefatsa Prototyping e potlakileng

Lebaleng le potlakileng la prototyping, moo netefatso e potlakileng le e nepahetseng e leng bohlokoa, li-V blocks li nka sebaka sa mantlha. Lisebelisoa tsena li thusa ho boloka likarolo tsa prototype nakong ea tlhahlobo le tlhahlobo, ho netefatsa hore lintlha tsa moralo lia fihlelleha pele li fetela tlhahisong e felletseng.

Precision in Aerospace le Defense

Liindastering tsa lifofane le tsa ts'ireletso, moo ho khomarela boleng bo thata le litekanyetso tsa polokeho ho ke keng ha buisanoa, li-V blocks li fetoha karolo ea bohlokoa. Sesebelisoa sena se bapala karolo ea bohlokoa tlhahisong e nepahetseng ea likarolo tsa bohlokoa, ho netefatsa ho lokisoa le lintlha tse nepahetseng tsa likarolo tsa sefofane le lisebelisoa tsa ts'ireletso.

Ts'ebeliso ea li-block tsa V ha e fapane feela empa e bohlokoa ho liindasteri tse etelletsang pele ho nepahala le ho nepahala. Ho tloha ho machining ho isa ho ho hlahloba, ho etsa lisebelisoa le ho etsa lisebelisoa ho isa tšebetsong ea ho kopanya, lisebelisoa tsena li eme e le lintlha tsa bohlokoa pokellong ea ts'ebetso e nepahetseng, e kenyang letsoho ho thehoeng ha likarolo tsa boleng bo holimo, tse tšepahalang le tse entsoeng ka makhethe.

Molemo oa ho Tsamaea Tseleng

• Tshebeletso e Sebetsang hantle le e Tshepehang;

• Boleng bo botle;

• Litheko tsa Tlholisano;

• OEM, ODM, OBM;

• Mefuta e mengata e fapaneng

• Phatlalatso e potlakileng le e ka tšeptjoang

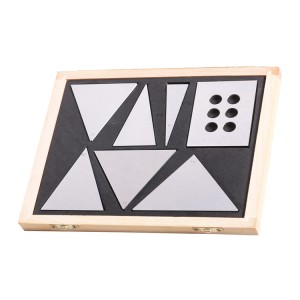

Litaba tsa Sephutheloana

1 x V Thibela

1 x Nyeoe ea Tšireletso

Tlaleho ea tlhahlobo ea 1x ka feme ea rona

● A na u hloka OEM, OBM, ODM kapa neutral packing bakeng sa lihlahisoa tsa hau?

● Lebitso la k'hamphani ea hau le lintlha tsa puisano bakeng sa maikutlo a potlakileng le a nepahetseng.

Ho feta moo, re u mema hore u kope mehlala ea tlhahlobo ea boleng.