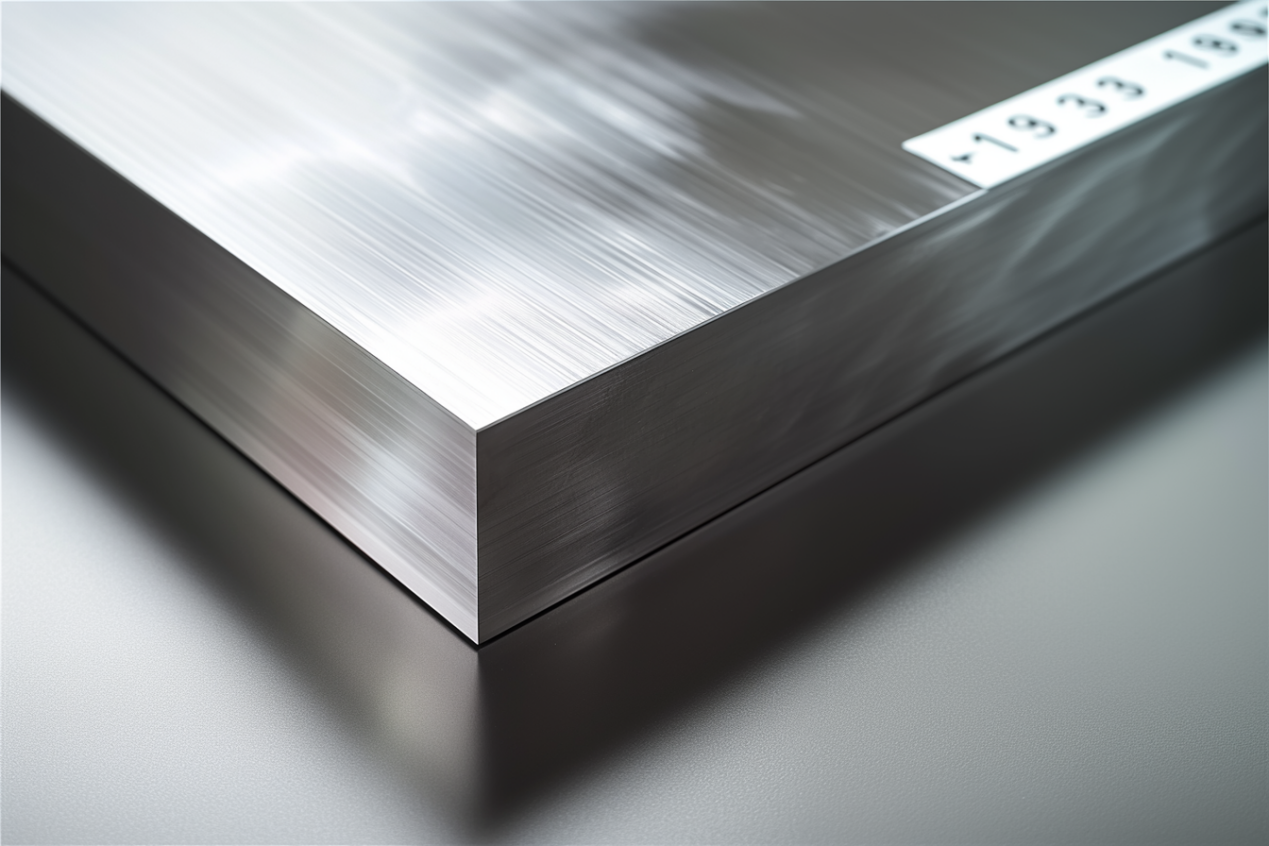

Metal Material

Tlhahisong ea morao-rao, ho khetha sesebelisoa se nepahetseng ke senotlolo sa ho netefatsa boleng ba sehlahisoa le tlhahiso. Leha ho le joalo, esita le "bahlabani ba indasteri" ba atisa ho lahleheloa ha ba tobane le mefuta e mengata ea lisebelisoa le litlhoko tsa mochine. Ho rarolla bothata bona, re hlophisitse tataiso ea lisebelisoa tsa machining ka lisebelisoa tse 50 tse tloaelehileng.

1. Aluminium Alloy

Aluminium alloy ke mofuta oa motsoako o entsoeng ka ho nka aluminium e le karolo ea mantlha le ho eketsa likarolo tse ling (tse kang koporo, magnesium, silicon, zinki, manganese, joalo-joalo). Ka lebaka la ts'ebetso ea eona e ntle haholo, e sebelisoa haholo mafapheng a mangata a kang sefofane, likoloi, kaho le ho paka.

Litšobotsi tsa lintho tse bonahalang: boima bo bobebe, matla a phahameng, ho hanyetsa kutu, ho sebetsa hantle, motlakase o motle le conductivity ea mocheso.

Lisebelisoa tse khothalelitsoeng: lisebelisoa tsa tšepe ea lebelo le phahameng (HSS), lithulusi tsa tungsten steel (carbide), lisebelisoa tse koahetsoeng, lisebelisoa tse koahetsoeng ka taemane (PCD), joalo kahss twist drill.

2. Tšepe e sa hloekang

Tšepe e sa hloekang ke motsoako oa tšepe o nang le chromium e seng ka tlase ho 10.5%, e hanyetsanang haholo le ho bola. E sebelisoa haholo kahong, lisebelisoa tsa bongaka, lisebelisoa tsa kichineng le lisebelisoa tsa lik'hemik'hale.

Litšobotsi tsa lintho tse bonahalang: ho hanyetsa kutu, ho hanyetsa mocheso, matla a phahameng a mochine, ho tiea hantle, ts'ebetso e ntle ea welding.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa carbide, ka ho khetheha lisebelisoa tse koahetsoeng (mohlala, TiN, TiCN). joalo kasebono se tiileng sa carbide.

3. Alloy ea Titanium

Li-alloys tsa Titanium ke li-alloys tse entsoeng ka titanium le likarolo tse ling (mohlala, aluminium, vanadium) 'me li sebelisoa haholo sebakeng sa lifofane, indasteri ea bongaka le ea lik'hemik'hale ka lebaka la matla a tsona a phahameng, boima bo bobebe le ho hanyetsa ho hotle ho hoholo.

Litšobotsi tsa thepa: matla a phahameng, letsoalo le tlase, ho hanyetsa kutu, ho hanyetsa mocheso o phahameng, modulus e tlase ea elasticity.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tse khethehileng tsa machining tsa titanium, joalo ka lisebelisoa tsa tšepe tsa ceramic kapa tsa tungsten. Joalo kacarbide tipped lesoba sehang.

4. Carbide e entsoeng ka samente

Carbide e entsoeng ka samente ke mofuta oa thepa e kopantsoeng e kopanyang tungsten carbide le cobalt, e nang le boima bo phahameng haholo le ho hanyetsa ho apara, e sebelisoang haholo ho seha lisebelisoa le li-abrasives.

Litšobotsi tsa lintho tse bonahalang: boima bo phahameng, matla a phahameng, ho hanyetsa ho roala, ho hanyetsa mocheso o motle, ho hanyetsa ka matla ho deformation.

Lisebelisoa tse khothalelitsoeng: lisebelisoa tsa PCD (polycrystalline diamond) kapa CBN (cubic boron nitride) lisebelisoa.

5. Koporo

Brass ke motsoako o entsoeng ka koporo le zinki, o sebelisoang haholo ho etseng motlakase, liphaephe le lisebelisoa tsa 'mino ka lebaka la thepa ea eona e ntle ea mochini le ho hanyetsa ho bola.

Litšobotsi tsa thepa: machinability e ntle, ho hanyetsa kutu, motlakase o motle le conductivity ea mocheso, ho hanyetsa ho apara.

Lisebelisoa tse khothalletsoang: lisebelisoa tse phahameng tsa tšepe (HSS) kapa tungsten steel (carbide), tse ka apesoang ho ntlafatsa ho hanyetsa ho apara. joalo kaHSS qetellong ea leloala.

6. Li-alloys tse thehiloeng ho nickel

Li-alloys tse thehiloeng ho nickel ke li-alloys tse phahameng tse entsoeng ka nickel le ho eketsoa ha chromium, molybdenum le likarolo tse ling. Li na le khanyetso e ntle haholo ea mocheso o phahameng le kutu, 'me hangata li sebelisoa libakeng tsa lifofane, sefofane le lik'hemik'hale.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, ho hanyetsa mocheso o phahameng, ho hanyetsa kutu, khanyetso ea oxidation, botsitso bo botle ba mocheso.

Lisebelisoa tse khothalletsoang: lisebelisoa tsa carbide, phekolo ea ho roala (e kang TiAlN) ho hanyetsa mocheso o phahameng le ho apara. joalo kasebono se tiileng sa carbide.

7. Koporo

Koporo ke tšepe e nang le motlakase o motle haholo oa motlakase le oa mocheso, o sebelisoang haholo ho lisebelisoa tsa motlakase, tsa kaho le tsa mocheso.

Litšobotsi tsa thepa: conductivity e ntle ea motlakase le ea mocheso, ho hanyetsa kutu, ho sebetsa habonolo, thepa ea antimicrobial.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tse phahameng tsa tšepe (HSS) kapa tungsten steel (carbide) ho netefatsa ho itšeha ho hloekile. joalo kahss twist drill.

8. Tšepe e lahliloeng

Cast iron ke mofuta oa alloy ea tšepe e nang le khabone e ngata. E na le ts'ebetso e ntle haholo ea ho lahla le ts'ebetso ea ho fokotsa matla a ho sisinyeha, 'me e sebelisoa haholo indastering ea ho etsa mechini, likoloi le masimong a kaho.

Litšobotsi tsa lintho tse bonahalang: boima bo phahameng, thepa e ntle ea ho lahla, thepa e ntle ea ho thothomela, ho hanyetsa, brittle.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa Carbide, hangata li sa koaheloa kapa li koahetsoe ka TiCN. joalo kasebono se tiileng sa carbide.

9. Li-Superalloys

Li-Superalloys ke sehlopha sa lisebelisoa tse nang le matla a mocheso o phahameng le khanyetso e ntle ea oxidation, e sebelisoang haholo indastering ea sefofane le matla.

Litšobotsi tsa thepa: matla a mocheso o phahameng, ho hanyetsa oxidation, khanyetso ea creep, ho hanyetsa kutu.

Lisebelisoa tse khothalletsoang: CBN (cubic boron nitride) kapa lisebelisoa tsa ceramic li loketse ho sebetsana le motsoako ona oa mocheso o phahameng.

10. Litšepe tse nang le mocheso

Litšepe tse chesitsoeng ka mocheso lia tingoa le ho halefa ho fana ka boima bo phahameng le matla, 'me hangata li sebelisoa ha ho etsoa lisebelisoa le hlobo.

Litšobotsi tsa lintho tse bonahalang: boima bo phahameng, matla a phahameng, ho hanyetsa ho apara, ho hanyetsa mocheso.

Lisebelisoa tse khothalelitsoeng: lisebelisoa tsa carbide kapa lisebelisoa tse koahetsoeng (mohlala, TiAlN), tse hanyetsanang le mocheso o phahameng le moaparo o phahameng. joalo kasebono se tiileng sa carbide.

11. Lisebelisoa tsa aluminium-magnesium

Lisebelisoa tsa aluminium-magnesium li thehiloe holim'a aluminium, 'me magnesium e kenyelelitsoe ho eketsa matla le ho hanyetsa ho bola,' me e sebelisoa haholo indastering ea lifofane le likoloi.

Litšobotsi tsa lintho tse bonahalang: bobebe, matla a phahameng, ho hanyetsa kutu, machinability e ntle.

Lisebelisoa tse khothalelitsoeng: Tungsten carbide (tungsten carbide) kapa lisebelisoa tsa tšepe ea lebelo le phahameng (HSS), tse atisang ho tlotsoa ka TiCN. joalo kahss twist drill.

12. Magnesium Alloys

Li-alloys tsa Magnesium ke li-alloys tse thehiloeng ho magnesium tse nang le boima bo bobebe le thepa e ntle ea mochini, e sebelisoang hangata sebakeng sa sefofane le lisebelisoa tsa elektroniki.

Litšobotsi tsa lintho tse bonahalang: boima bo bobebe, machinability e ntle, conductivity e ntle ea mocheso, ho chesa.

Lisebelisoa tse khothalelitsoeng: tšepe ea tungsten (tungsten carbide) kapa lisebelisoa tsa tšepe e phahameng ka potlako (HSS). Sebaka se tlaase sa ho qhibiliha le ho chesa ha thepa ho lokela ho nahanoa. joalo kasebono se tiileng sa carbide.

13. Titanium e hloekileng

Titanium e hloekileng e na le mefuta e mengata ea lisebelisoa sebakeng sa lifofane, tsa bongaka le tsa lik'hemik'hale ka lebaka la matla a eona a phahameng, ho fokotseha ha sekhahla le ho hanyetsa ho hotle ha kutu.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, letsoalo le tlase, ho hanyetsa kutu, ho lumellana hantle le biocompatibility.

Lisebelisoa tse khothalelitsoeng: lisebelisoa tsa carbide tse etselitsoeng ka ho khetheha kapa lisebelisoa tsa ceramic tse hlokang ho koaheloa le ho thibela ho khomarela. joalo kasebono se tiileng sa carbide.

14. Lisebelisoa tsa zinki

Li-alloys tsa zinki li entsoe ka zinki le ho eketsoa ha likarolo tse ling (mohlala, aluminium, koporo) 'me li sebelisoa haholo bakeng sa likarolo tse sa tšoaneng le lintho tse khabisitsoeng.

Litšobotsi tsa thepa: ho lahla habonolo, sebaka se tlase se qhibilihang, thepa e ntle ea mochini le ho hanyetsa kutu.

Lisebelisoa tse khothalletsoang: Lisebelisoa tse phahameng tsa tšepe (HSS) kapa tungsten steel (tungsten carbide) ho netefatsa phello ea ho itšeha le boleng ba holim'a metsi. joalo kahss twist drill.

15. Nickel-titanium alloy (Nitinol)

Nitinol ke motsoako o nang le phello ea memori le superelasticity, e sebelisoang haholo lisebelisoa tsa bongaka le aerospace.

Litšobotsi tsa lintho tse bonahalang: phello ea memori, superelasticity, khanyetso e phahameng ea kutu, biocompatibility e ntle.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa carbide, khanyetso e phahameng ea ho roala le thepa ea mocheso e phahameng ea hlokahala. joalo kasebono se tiileng sa carbide.

16. Magnesium-aluminium alloys

Magnesium-aluminium alloy e kopanya melemo ea magnesium le aluminium, e nang le boima bo bobebe le matla a phahameng, e sebelisoang haholo indastering ea lifofane le tsa likoloi.

Litšobotsi tsa lintho tse bonahalang: bobebe, matla a phahameng, ho hanyetsa kutu, machinability e ntle, ho cha.

Lisebelisoa tse khothalletsoang: lisebelisoa tse phahameng tsa tšepe (HSS) kapa tungsten steel (carbide), ho nahanela ho chesa ha thepa. joalo kahss twist drill.

17. Litšepe tse thata tse phahameng haholo

Litšepe tse thata tse phahameng haholo li tšoaroa ka ho khetheha ho fana ka boima bo phahameng ka ho fetesisa le ho se mamelle 'me li sebelisoa hangata ho etsa hlobo le ho etsa lisebelisoa.

Litšobotsi tsa thepa: boima bo phahameng haholo, matla a phahameng, ho hanyetsa ho roala, ho hanyetsa mocheso o phahameng.

Lisebelisoa tse khothalelitsoeng: CBN (Cubic Boron Nitride) kapa lisebelisoa tsa ceramic bakeng sa ho sebetsa ka thata haholo.

18. Lisebelisoa tsa khauta

Lisebelisoa tsa khauta li entsoe ka khauta e kopantsoeng le likarolo tse ling tsa tšepe (tse kang silevera, koporo) 'me li sebelisoa haholo mabenyaneng, lisebelisoa tsa elektronike le lisebelisoa tsa bongaka.

Litšobotsi tsa lintho tse bonahalang: conductivity e ntle ea motlakase le mocheso, ho hanyetsa kutu, ductility e phahameng, khanyetso ea oxidation.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa tšepe tse phahameng ka lebelo (HSS) kapa tungsten steel (carbide) ho netefatsa ho nepahala le ho qeta ts'ebetsong ea ho itšeha. joalo kasebono se tiileng sa carbide.

19. Lisebelisoa tsa silevera

Lisebelisoa tsa silevera li entsoe ka silevera e kopantsoeng le likarolo tse ling tsa tšepe (mohlala, koporo, zinki) 'me li sebelisoa haholo likarolong tsa motlakase, mabenyane le licheleteng tsa tšepe.

Litšobotsi tsa lintho tse bonahalang: conductivity e ntle ea motlakase le ea mocheso, ho hanyetsa kutu, ductility e phahameng.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa tšepe e phahameng ka lebelo (HSS) kapa tungsten steel (carbide), tse hlokang ho ba bohale le ho tšoarella. Joalo kasebono se tiileng sa carbide.

20. Tšepe ea Chromium-molybdenum

Chromium-molybdenum tšepe ke tšepe e nang le matla a phahameng a tlaase a alloy e nang le likarolo tsa chromium le molybdenum, e sebelisoang haholo likepeng tsa khatello, lisebelisoa tsa petrochemical le likarolo tsa mechine.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, boima bo botle, ho hanyetsa ho apara, mocheso o phahameng le ho senya.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa Carbide, tse loketseng machining a tšepe a alloy a phahameng. joalo kasebono se tiileng sa carbide.

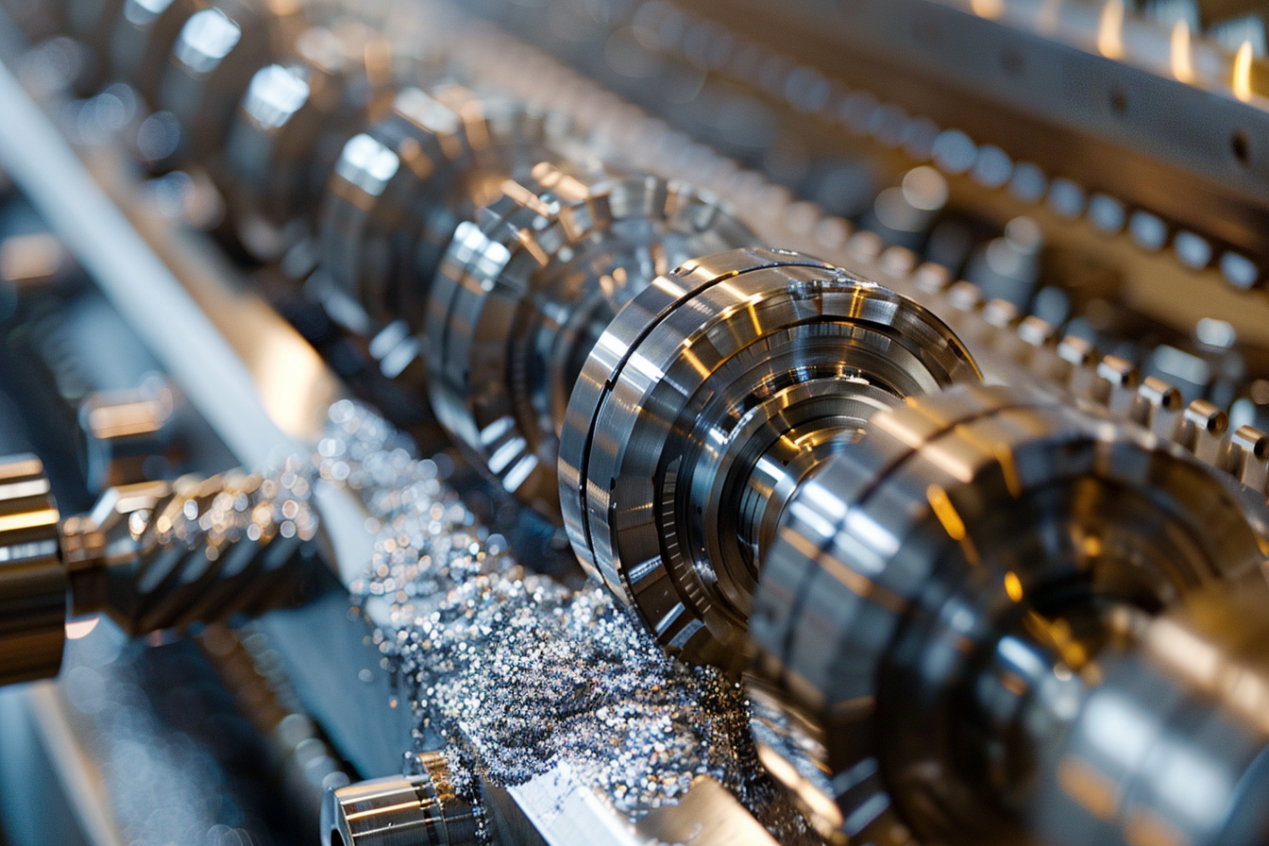

Litšoantšo

21. Tšepe ea Tungsten

Tungsten tšepe ke motsoako o thata o entsoeng ka tungsten carbide le cobalt. E na le boima bo phahameng ka ho fetesisa le ho hanyetsa 'me e sebelisoa haholo ha ho etsoa lisebelisoa tsa ho itšeha le li-abrasives.

Litšobotsi tsa lintho tse bonahalang: Ho thatafala ho feteletseng, ho hanyetsa ho roala, ho hanyetsa mocheso o phahameng, le ho hanyetsa deformation.

Lisebelisoa tse khothalelitsoeng: CBN (Cubic Boron Nitride) kapa lisebelisoa tsa daemane (PCD), tse loketseng ho sebetsana le lisebelisoa tse thata tse phahameng.

22. Alloy ea Tungsten-cobalt

Tungsten-cobalt alloy ke motsoako o thata o nang le tungsten le cobalt e nang le matla a phahameng le ho hanyetsa ho apara, e sebelisoang hangata ho seha le ho sila lisebelisoa.

Litšobotsi tsa thepa: matla a phahameng, ho hanyetsa ho roala, ho hanyetsa mocheso o motle, le ho hanyetsa matla a phahameng.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa carbide tse entsoeng ka samente, tse sa senyeheng le tse matla haholo.

23. motsoako oa koporo oa beryllium

Beryllium koporo alloy e na le koporo le beryllium, e nang le thepa e babatsehang ea mochine le motlakase oa motlakase, o sebelisoang haholo ha ho etsoa liliba, likarolo tsa ho ikopanya le lisebelisoa.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, boima bo phahameng, motlakase o motle le conductivity ea mocheso, khanyetso ea kutu, e seng ea makenete.

Lisebelisoa tse khothalelitsoeng: lisebelisoa tse phahameng tsa tšepe (HSS) kapa tungsten steel (carbide) ho netefatsa ho nepahala ha machining le ho qeta holimo. Joalo kasebono se tiileng sa carbide.

24. Alloy e phahameng ea mocheso (Inconel)

Inconel ke motsoako oa mocheso o phahameng oa nickel-chromium o nang le mocheso o phahameng haholo le ho hanyetsa kutu, o sebelisoang haholo sebakeng sa sefofane le lisebelisoa tsa lik'hemik'hale.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, ho hanyetsa mocheso o phahameng, ho hanyetsa kutu, khanyetso ea oxidation, botsitso bo botle ba mocheso.

Lisebelisoa tse khothalletsoang: lisebelisoa tsa carbide kapa lisebelisoa tsa ceramic, phekolo ea ho roala (e kang TiAlN) ho hanyetsa mocheso o phahameng. Joalo kasebono se tiileng sa carbide.

25. Tšepe e entsoeng ka chromium e phahameng

High-chromium cast iron ke mofuta oa tšepe e entsoeng ka tšepe e nang le chromium e phahameng, e nang le ts'ebetso e ntle haholo ea ho koaleha le ho hanyetsa ho bola, e sebelisoang hangata lithulusing tsa abrasive le likarolo tsa ho roala.

Litšobotsi tsa lintho tse bonahalang: boima bo phahameng, khanyetso e phahameng ea ho apara, khanyetso e ntle ea kutu, khanyetso ea oxidation.

Lisebelisoa tse khothalelitsoeng: lisebelisoa tsa carbide kapa CBN (cubic boron nitride) lisebelisoa tsa lisebelisoa tsa tšepe tse thata tse phahameng. Joalo kasebono se tiileng sa carbide.

26. Tšepe e phahameng ea manganese

Ts'epe e phahameng ea manganese ke mofuta oa ts'ireletso e phahameng ea ho roala le tšepe e matla e nang le tšusumetso e matla, e sebelisoang haholo mecheng ea merafo le lisebelisoa tsa terene.

Litšobotsi tsa lintho tse bonahalang: khanyetso e phahameng ea ho roala, matla a phahameng, ho hanyetsa tšusumetso e ntle, ho thatafala ho apara.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa carbide, tse sa senyeheng le tse matla haholo. Joalo kasebono se tiileng sa carbide.

27. Lisebelisoa tsa molybdenum

Li-alloys tsa molybdenum li na le element molybdenum, li na le matla a phahameng le boima bo phahameng, 'me hangata li sebelisoa e le lisebelisoa tsa tlhophiso maemong a mocheso o phahameng le a matla a phahameng.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, boima bo phahameng, ho hanyetsa mocheso o phahameng, ho hanyetsa kutu.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa Carbide, tse loketseng matla a phahameng le lisebelisoa tsa alloy tse thata. Joalo kasebono se tiileng sa carbide.

28. Tšepe ea Carbon

Tšepe ea carbon ke tšepe e nang le carbon content pakeng tsa 0.02% le 2.11%. Thepa ea eona e fapana ho ea ka carbon content 'me e atisa ho sebelisoa kahong, marokho, likoloi le kaho ea likepe.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, toughness e ntle le polasetiki, e theko e tlaase, e bonolo ho tjheseletsa le ho tšoara mocheso.

Lisebelisoa tse khothalelitsoeng: tšepe ea lebelo le phahameng (HSS) kapa lisebelisoa tsa carbide bakeng sa mochini o tloaelehileng oa tšepe ea carbon.

29. Litšepe tse tlaase tsa alloy

Litšepe tse nang le alloy e tlase ke litšepe tseo thepa ea tsona e ntlafatsoang ka ho eketsoa ha likaroloana tse nyane tsa motsoako (mohlala, chromium, nickel, molybdenum) 'me li sebelisoa haholo boenjiniere ba mechini le boenjiniere ba meralo.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, toughness e ntle, ho hanyetsa ho roala, machining a bonolo.

Lisebelisoa tse khothalelitsoeng: Litšepe tse lebelo le phahameng (HSS) kapa lisebelisoa tsa carbide bakeng sa machining ka kakaretso. Joalo kasebono se tiileng sa carbide.

30. Litšepe tse matla haholo

Litšepe tse matla tse phahameng li kenngoa mocheso kapa lisebelisoa tsa alloying li eketsoa ho fumana matla a phahameng le ho thatafala, 'me hangata li sebelisoa indastering ea likoloi le boenjiniere ba kaho.

Litšobotsi tsa lintho tse bonahalang: matla a phahameng, boima bo phahameng, ho hanyetsa ho roala, boima bo botle.

Lisebelisoa tse khothalelitsoeng: Lisebelisoa tsa Carbide bakeng sa ho hanyetsa ho roala le matla a phahameng. Joalo kasebono se tiileng sa carbide.

● A na u hloka OEM, OBM, ODM kapa neutral packing bakeng sa lihlahisoa tsa hau?

● Lebitso la k'hamphani ea hau le lintlha tsa puisano bakeng sa maikutlo a potlakileng le a nepahetseng.

Ho feta moo, re u mema hore u kope mehlala ea tlhahlobo ea boleng.

jason@wayleading.com

+8613666269798

Nako ea poso: May-18-2024