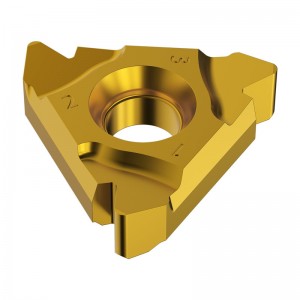

HSS Module Involute Gear Cutters Ka PA20 Le PA14-1/2

Kenyelletsa li-Gear Cutters

● #1 sehang bakeng sa 12&13 Cuts gears

● #2 sehahi bakeng sa 14-16 Cuts gears

● #3 sehahi bakeng sa 17-20 Cuts gears

● #4 sehahi bakeng sa 21-25 Cuts gears

● #5 sehahi bakeng sa 26-34 Cuts gears

● #6 sehahi bakeng sa 35-54 Cuts gears

● #7 sehahi bakeng sa 55-134 Cuts gears

● #8 sehang bakeng sa 135 ho Rack Cuts likere

Mofuta oa PA20

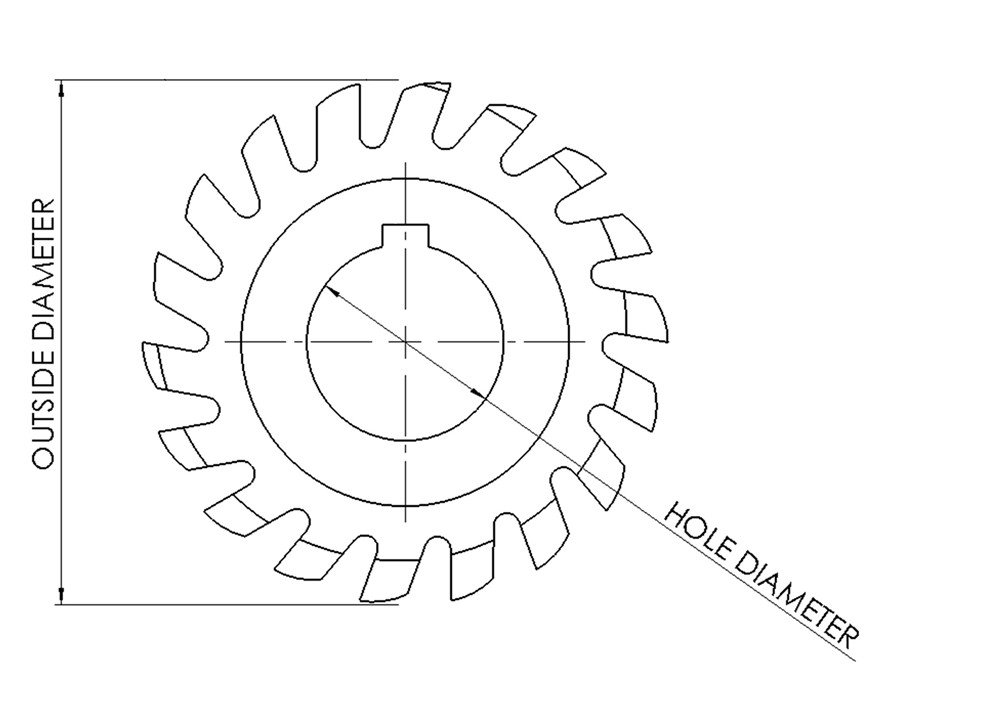

| MODULE | MOTS'OETSI DIA. | SEKOBA DIA. | 8pcs/sete |

| 0.50 | 40 | 16 | 660-7692 |

| 0.70 | 40 | 16 | 660-7693 |

| 0.80 | 40 | 16 | 660-7694 |

| 1.00 | 50 | 16 | 660-7695 |

| 1.25 | 50 | 16 | 660-7696 |

| 1.50 | 56 | 22 | 660-7697 |

| 1.75 | 56 | 22 | 660-7698 |

| 2.00 | 63 | 22 | 660-7699 |

| 2.25 | 63 | 22 | 660-7700 |

| 2.50 | 63 | 22 | 660-7701 |

| 2.75 | 71 | 27 | 660-7702 |

| 3.00 | 71 | 27 | 660-7703 |

| 3.25 | 71 | 27 | 660-7704 |

| 3.50 | 80 | 27 | 660-7705 |

| 3.75 | 80 | 27 | 660-7706 |

| 4.00 | 80 | 27 | 660-7707 |

| 4.50 | 90 | 32 | 660-7708 |

| 5.00 | 90 | 32 | 660-7709 |

| 5.50 | 90 | 32 | 660-7710 |

| 6.00 | 100 | 32 | 660-7711 |

| 6.50 | 100 | 32 | 660-7712 |

| 7.00 | 100 | 32 | 660-7713 |

| 8 | 112 | 32 | 660-7714 |

| 9 | 125 | 32 | 660-7715 |

| 10 | 15 | 40 | 660-7716 |

| 11 | 140 | 40 | 660-7717 |

| 12 | 140 | 40 | 660-7718 |

| 14 | 160 | 40 | 660-7719 |

| 16 | 180 | 50 | 660-7720 |

| 18 | 200 | 50 | 660-7721 |

| 20 | 200 | 50 | 660-7722 |

Mofuta oa PA14-1/2

| MODULE | MOTS'OETSI DIA. | SEKOBA DIA. | 8pcs/sete |

| 0.50 | 40 | 16 | 660-7723 |

| 0.70 | 40 | 16 | 660-7724 |

| 0.80 | 40 | 16 | 660-7725 |

| 1.00 | 50 | 16 | 660-7726 |

| 1.25 | 50 | 16 | 660-7727 |

| 1.50 | 56 | 22 | 660-7728 |

| 1.75 | 56 | 22 | 660-7729 |

| 2.00 | 63 | 22 | 660-7730 |

| 2.25 | 63 | 22 | 660-7731 |

| 2.50 | 63 | 22 | 660-7732 |

| 2.75 | 71 | 27 | 660-7733 |

| 3.00 | 71 | 27 | 660-7734 |

| 3.25 | 71 | 27 | 660-7735 |

| 3.50 | 80 | 27 | 660-7736 |

| 3.75 | 80 | 27 | 660-7737 |

| 4.00 | 80 | 27 | 660-7738 |

| 4.50 | 90 | 32 | 660-7739 |

| 5.00 | 90 | 32 | 660-7740 |

| 5.50 | 90 | 32 | 660-7741 |

| 6.00 | 100 | 32 | 660-7742 |

| 6.50 | 100 | 32 | 660-7743 |

| 7.00 | 100 | 32 | 660-7744 |

| 8 | 112 | 32 | 660-7745 |

| 9 | 125 | 32 | 660-7746 |

| 10 | 15 | 40 | 660-7747 |

| 11 | 140 | 40 | 660-7748 |

| 12 | 140 | 40 | 660-7749 |

| 14 | 160 | 40 | 660-7750 |

| 16 | 180 | 50 | 660-7751 |

| 18 | 200 | 50 | 660-7752 |

| 20 | 200 | 50 | 660-7753 |

Kopo

Mesebetsi ea Gear Cutter:

1. Lisebelisoa tsa Gear: Li-gear cutters li sebelisetsoa ho sila litlaleho tsa likere, ho netefatsa boholo le libopeho tse nepahetseng. Sena se kenyelletsa mefuta e fapaneng ea likere tse joalo ka likere tsa spur, likere tsa helical le likere tsa seboko.

2. Gear Truing: Nakong ea tlhahiso, li-gear cutters li boetse li sebelisoa ho netefatsa kapa ho lokisa bokaholimo ba likere ho fihlela litlhoko tsa moralo.

3. Ho nepahala: Li-gear cutters li etsa bonnete ba hore li-gear li finyella ho nepahala ho phahameng ka litekanyo le libopeho tsa geometri, tsa bohlokoa bakeng sa ts'ebetso e bonolo le ts'ebetso ea mekhoa ea phetisetso.

Ts'ebetso e Atlehang: Ho sebelisa li-gear cutters ho ka fihlela mochini o sebetsang hantle oa lisebelisoa, ho ntlafatsa katleho ea tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso.

4. Mefuta-futa: Li-gear cutters li ka sebelisoa eseng feela bakeng sa lisebelisoa tsa tšepe empa hape le bakeng sa lisebelisoa tse entsoeng ka thepa e kang polasetiki le lehong, tse fanang ka mefuta e mengata ea lisebelisoa.

Tšebeliso le Litlhokomelo Bakeng sa Sekhahla sa Gear:

Tšebeliso:

Khetho ea Cutter: Khetha seha se nepahetseng sa lisebelisoa ho latela mofuta le thepa ea lisebelisoa tse tla etsoa ka mochini, hammoho le litlhaloso le mamello tse lakatsehang.

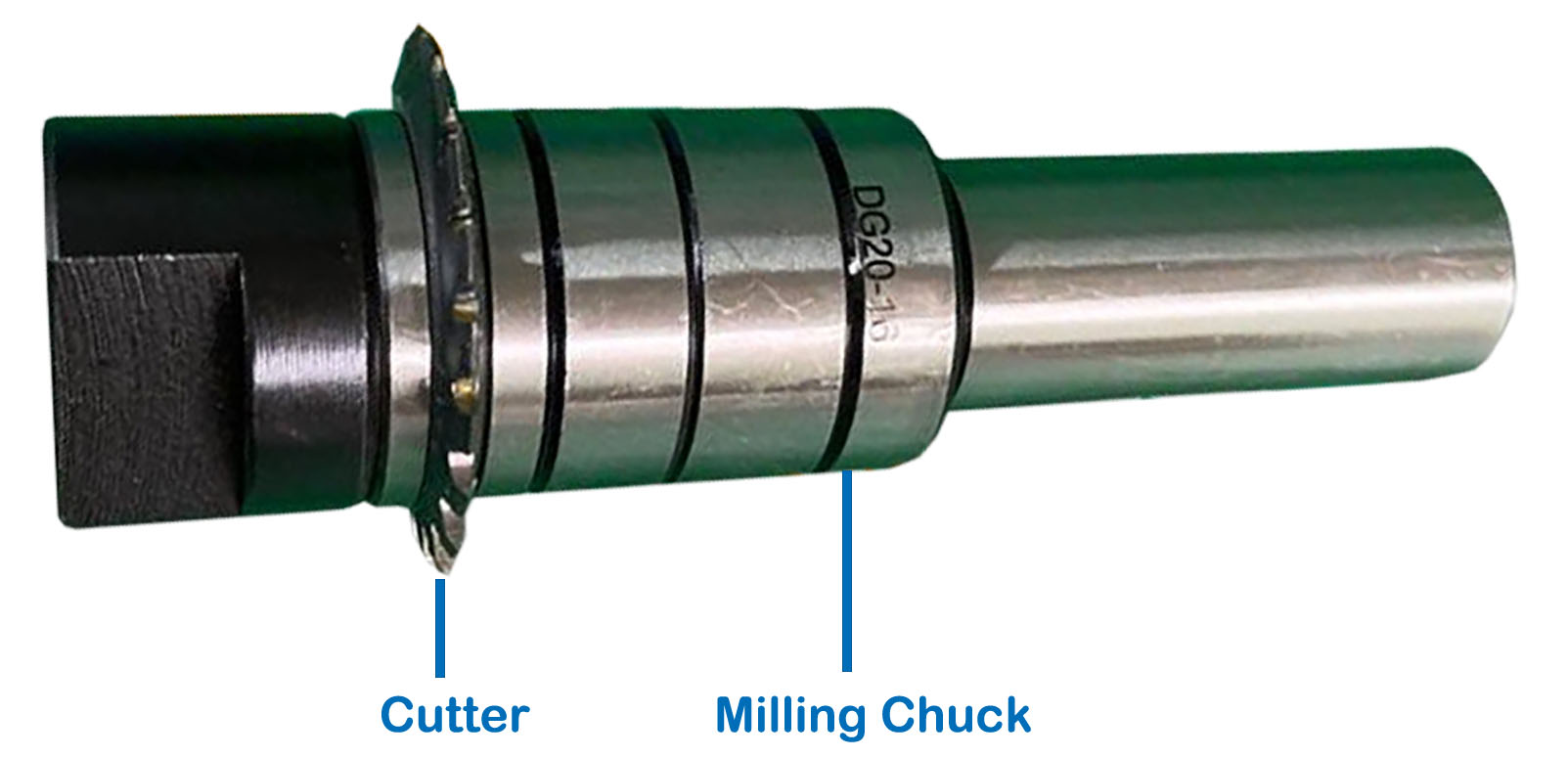

Setupo: Beha sehahi ka mokhoa o sireletsehileng mochining oa ho sila ka mokhoa o sireletsehileng, ho netefatsa teka-tekano e nepahetseng le boteng.

Fixturing Workpiece: Thibela sesebediswa ka polokeho tafoleng ea mochini o silang, ho netefatsa botsitso le boemo bo nepahetseng bakeng sa mochini o nepahetseng.

Li-Parameters tsa ho itšeha: Beha litekanyetso tsa ho itšeha joalo ka lebelo, sekhahla sa phepelo, le botebo ba sehiloeng ho latela thepa le boholo ba lisebelisoa, hammoho le bokhoni ba mochini o silang.

Ts'ebetso ea Machining: Phetha ts'ebetso ea ho sila ka hloko, u netefatse hore mochini oa ho sila o tsamaea hantle le o tsitsitseng ho pholletsa le sebaka sa mosebetsi ho fihlela boemo bo lakatsehang ba lisebelisoa le boholo.

Tšebeliso ea Sepholi: Ho ipapisitse le thepa e ntseng e etsoa ka mochini, sebelisa sepholi kapa setlolo ho theola mocheso le ho ntlafatsa phallo ea chip, ho netefatsa ts'ebetso e ntle ea ho itšeha le ho lelefatsa bophelo ba lisebelisoa.

Mehato ya tlhokomelo:

Lisebelisoa tsa Tšireletso: Kamehla u roale lisebelisoa tse nepahetseng tsa tšireletso tse kang likhalase, liatlana, le ts'ireletso ea litsebe ho thibela likotsi tse bakoang ke lichipisi tse fofang, lerata le likotsi tse ling.

Tlhahlobo ea Lisebelisoa: Kamehla hlahloba sekheo sa li-gear bakeng sa matšoao a ho khathala, ho senyeha kapa ho fokola. Tlosa li-cutters tse tsofetseng kapa tse senyehileng kapele ho boloka boleng ba mochini le ho thibela likotsi.

Tlhokomelo ea Mochini: Boloka mochini o silang o le maemong a matle a ho sebetsa ka ho etsa mesebetsi ea kamehla ea ho lokisa joalo ka ho hloekisa, ho tlotsa le ho lekanya, ho netefatsa ts'ebetso e nepahetseng le polokeho.

Tool Handling: Tšoara li-gear cutters ka hloko ho qoba ho liha kapa ho li tšoara hampe, tse ka bakang tšenyo kapa kotsi. Sebelisa mekhoa e nepahetseng ea ho phahamisa le mekhoa ea polokelo ho boloka botšepehi ba sesebelisoa.

Taolo ea Chip: Laola lichifi le li-swarf hantle tse hlahisoang nakong ea mochini ho thibela ho bokellana le ho kena-kenana le ts'ebetso ea ho itšeha kapa likarolo tsa mochini.

Koetliso ea Basebetsi: Netefatsa hore basebetsi ba koetlisoa ka ho lekaneng le ho tloaelana le ts'ebetso ea li-gear cutters, ho kenyeletsoa mekhoa ea polokeho le mekhoa e nepahetseng ea mochini.

Molemo

Tshebeletso e Sebetsang hantle le e Tshepehang

Lisebelisoa tsa Wayleading, morekisi oa hau oa sebaka se le seng bakeng sa lisebelisoa tsa ho seha, lisebelisoa tsa mochini, lisebelisoa tsa ho lekanya. Joalo ka setsi se kopaneng sa matla a indasteri, re motlotlo haholo ka Ts'ebeletso ea rona e Sebetsang le e Tšepahalang, e etselitsoeng ho fihlela litlhoko tse fapaneng tsa bareki ba rona ba hlomphuoang. Tobetsa Mona Bakeng sa Tse ling

Boleng bo Botle

Ho Lisebelisoa tsa Wayleading, boitlamo ba rona ba Boleng bo Botle bo re khetholla re le matla a maholo indastering. Joaloka setsi sa motlakase se kopantsoeng, re fana ka mefuta e fapaneng ea litharollo tsa indasteri tse tsoetseng pele, tse u fang lisebelisoa tse ntlehali tsa ho itšeha, lisebelisoa tse nepahetseng tsa ho lekanya, le lisebelisoa tse tšepahalang tsa mochini.TobetsaMona Bakeng sa Tse ling

Litheko tsa tlhōlisano

Rea u amohela ho Wayleading Tools, morekisi oa hau o le mong bakeng sa lisebelisoa tsa ho itšeha, lisebelisoa tsa ho lekanya, lisebelisoa tsa mochini. Re motlotlo haholo ka ho fana ka Litheko tsa Tlholisano e le o mong oa melemo ea rona ea mantlha.Tobetsa Mona Bakeng sa Tse ling

OEM, ODM, OBM

Ho Lisebelisoa tsa Wayleading, re motlotlo ka ho fana ka lits'ebeletso tse felletseng tsa OEM (Moetsi oa Lisebelisoa tsa Original), ODM (Original Design Manufacturer), le OBM (Own Brand Manufacturer), tse fanang ka litlhoko le mehopolo ea hau e ikhethang.Tobetsa Mona Bakeng sa Tse ling

Mefuta e sa tšoaneng e Atolositsoeng

Rea u amohela ho Wayleading Tools, sebaka seo u eang ho sona bakeng sa litharollo tsa morao-rao tsa indasteri, moo re ipabolang ka ho seha lisebelisoa, lisebelisoa tsa ho metha, le lisebelisoa tsa mochini. Monyetla oa rona oa mantlha ke ho fana ka mefuta e mengata e fapaneng ea lihlahisoa, tse etselitsoeng ho fihlela litlhoko tse fapaneng tsa bareki ba rona ba hlomphuoang.Tobetsa Mona Bakeng sa Tse ling

Lintho tse Tšoanang

Tharollo

Tšehetso ea tekheniki:

Re thabetse ho ba mofani oa hau oa tharollo bakeng sa ER collet. Re thabela ho u fa tšehetso ea tekheniki. Ebang ke nakong ea thekiso ea hau kapa ts'ebeliso ea bareki ba hau, ha re fumana lipotso tsa hau tsa tekheniki, re tla araba lipotso tsa hau hanghang. Re tšepisa ho araba nakong ea lihora tse 24 haufinyane, re u fa litharollo tsa tekheniki.Tobetsa Mona Bakeng sa Tse ling

Litšebeletso tse ikhethileng:

Re thabela ho u fa lits'ebeletso tse ikhethileng tsa ER collet. Re ka fana ka litšebeletso tsa OEM, lihlahisoa tsa tlhahiso ho latela litšoantšo tsa hau; Litšebeletso tsa OBM, ho hlahisa lihlahisoa tsa rona ka letšoao la hau; le lits'ebeletso tsa ODM, ho fetola lihlahisoa tsa rona ho latela litlhoko tsa moralo oa hau. Ho sa tsotellehe hore na u hloka litšebeletso life, re tšepisa ho u fa litharollo tsa profeshenale.Tobetsa Mona Bakeng sa Tse ling

Litšebeletso tsa Koetliso:

Hore na o moreki oa lihlahisoa tsa rona kapa o mosebelisi oa ho qetela, re thabela ho fana ka ts'ebeletso ea koetliso ho netefatsa hore o sebelisa lihlahisoa tseo o li rekileng ho rona ka nepo. Lisebelisoa tsa rona tsa koetliso li tla ka litokomane tsa elektroniki, livideo le liboka tsa marang-rang, tse u lumellang ho khetha khetho e loketseng ka ho fetisisa. Ho tloha kopo ea hau ea koetliso ho isa ho phano ea litharollo tsa koetliso, re ts'episa ho phethela ts'ebetso eohle nakong ea matsatsi a 3Tobetsa Mona Bakeng sa Tse ling

Tšebeletso ka mor'a thekiso:

Lihlahisoa tsa rona li tla le nako ea tšebeletso ea likhoeli tse 6 ka mor'a thekiso. Nakong ena, mathata leha e le afe a sa hlahisoang ka boomo a tla nkeloa sebaka kapa a lokisoe ntle ho tefo. Re fana ka ts'ehetso ea litšebeletso tsa bareki bosiu le motšehare, ho sebetsana le lipotso kapa litletlebo life kapa life, ho netefatsa hore u na le boiphihlelo bo monate ba ho reka.Tobetsa Mona Bakeng sa Tse ling

Moralo oa Tharollo:

Ka ho fana ka moralo oa sehlahisoa sa hau sa machining (kapa ho thusa ho theha litšoantšo tsa 3D haeba li le sieo), litlhaloso tsa thepa, le lintlha tsa mochini tse sebelisitsoeng, sehlopha sa rona sa sehlahisoa se tla hlophisa likhothaletso tse loketseng bakeng sa lisebelisoa tsa ho seha, lisebelisoa tsa mochini le lisebelisoa tsa ho lekanya, le ho rala litharollo tse felletseng tsa machining. molemong oa hau.Tobetsa Mona Bakeng sa Tse ling

Ho paka

E phuthetsoe ka lebokoseng la polasetiki ka mokotla oa ho fokotsa mocheso. Ebe e kenngoa ka lebokoseng le ka ntle. E ka thijoa hantle hore e se ke ea rusa.

Hape ho phutheloa ka mokhoa o ikhethileng ho amoheloa.

Automotive Gear Production Precision

Module Involute Gear Cutter ke sesebelisoa se ikhethileng haholo, se bohlokoa haholo lefapheng la tlhahiso ea lisebelisoa. E etselitsoe ho hlahisa likere tse nang le li-profiles tse nepahetseng, li-cutters tsena li fumaneha ka boholo bo fapaneng ba li-module ho amohela mefuta e fapaneng ea litekanyo tsa lisebelisoa.

Tlhahisong ea likoloi, li-Module Involute Gear Cutters li bohlokoa bakeng sa ho hlahisa lisebelisoa tse rarahaneng tse sebelisoang phetisong le phapang. Ho nepahala ha li-cutters tsena ho etsa bonnete ba hore likere li tsamaea hantle, 'me sena se thusa ho sebetsa hantle le ho sebetsa ha koloi ka kakaretso.

Litlhoko tsa Lisebelisoa tsa Aerospace Industry

Indastering ea sepaka-paka, tlhokahalo ea likere tse nepahetseng haholo lienjineng tsa lifofane le lisebelisoa tsa lisebelisoa tse thellang li etsa hore likhechana tsena e be tsa bohlokoa haholo. Li sebelisetsoa ho etsa likere tse khonang ho mamella maemo a feteletseng le meroalo, e leng tlhokahalo ea bohlokoa lits'ebetsong tsa sefofane.

Tlhahiso ea Mechini e Meholo e Meholo

Ha ho etsoa mechini e boima le lisebelisoa tsa indasteri, li-Module Involute Gear Cutters li sebelisoa ho hlahisa likere tse kholo tse hlokahalang bakeng sa mechini e kang crane, literekere le litsamaiso tse tsamaisang thepa. Ho tiea le ho nepahala ha li-cutters tsena ho bohlokoa bakeng sa ho netefatsa bophelo bo bolelele le ho ts'epahala ha mechini ena e meholo.

Liroboto le Li-Gears tsa Boiketsetso

Ho feta moo, lebaleng la liroboto le li-automation, li-gear cutters tsena li sebelisetsoa ho etsa likere tse nyane, tse nepahetseng haholo. Li-gear tsena ke likarolo tsa bohlokoa lits'ebetsong tsa liroboto, moo motsamao o nepahetseng le taolo e leng bohlokoa.

Mekhoa e sa tšoaneng ea ho Fetola Gear Fabrication

Ntle le moo, sebakeng sa tlhahiso ea lisebelisoa tsa tloaelo, Module Involute Gear Cutters e fana ka monyetla oa ho hlahisa likere tse nang le litlhoko tse ikhethileng. Ebang ke bakeng sa mochini o ikhethileng kapa likarolo tse ncha tsa lisebelisoa tsa khale, li-cutters tsena li thusa ho hlahisa likere tse fihlelang hantle.

Bokhoni ba Module Involute Gear Cutter ea ho hlahisa likere tse nang le lintlha tse hlakileng tse kenyelletsang liindasteri tse fapaneng, ho tloha ho tsa likoloi ho ea ho tsa sefofane le tsa indasteri, li totobatsa bohlokoa ba eona tlhahisong ea sejoale-joale. Ho feto-fetoha ha eona ho theheng likere tsa boholo bo fapaneng le litlhaloso ho e etsa sesebelisoa sa bohlokoa bakeng sa ts'ebetso efe kapa efe ea tlhahiso ea lisebelisoa.

Molemo oa ho Tsamaea Tseleng

• Tshebeletso e Sebetsang hantle le e Tshepehang;

• Boleng bo botle;

• Litheko tsa Tlholisano;

• OEM, ODM, OBM;

• Mefuta e mengata e fapaneng

• Phatlalatso e potlakileng le e ka tšeptjoang

Litaba tsa Sephutheloana

1 x HSS Module Involute Gear Cutters

● A na u hloka OEM, OBM, ODM kapa neutral packing bakeng sa lihlahisoa tsa hau?

● Lebitso la k'hamphani ea hau le lintlha tsa puisano bakeng sa maikutlo a potlakileng le a nepahetseng.

Ho feta moo, re u mema hore u kope mehlala ea tlhahlobo ea boleng.