HSS e Kenyelletsa Spline Cutter Ka PA30

Kenyelletsa Spline Cutter

● #1 sehang bakeng sa 12&13 Cuts gears

● #2 sehahi bakeng sa 14-16 Cuts gears

● #3 sehahi bakeng sa 17-20 Cuts gears

● #4 sehahi bakeng sa 21-25 Cuts gears

● #5 sehahi bakeng sa 26-34 Cuts gears

● #6 sehahi bakeng sa 35-54 Cuts gears

● #7 sehahi bakeng sa 55-134 Cuts gears

● #8 sehang bakeng sa 135 ho Rack Cuts likere

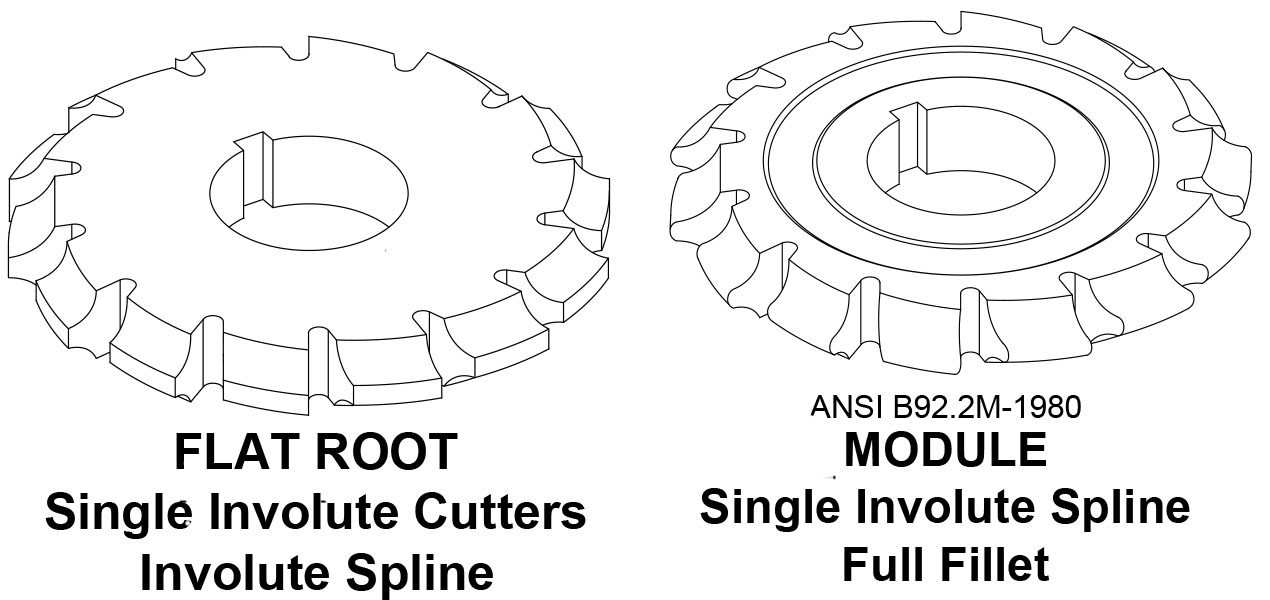

Motso o bataletseng

Fillet e felletseng

| Module Pitch | Cutter Dia. | Sekoti sa boholo | 8pcs/sete |

| 0.5 | 2-1/2 | 1 | 660-8767 |

| 0.75 | 2-3/4 | 1 | 660-8768 |

| 1 | 3 | 1 | 660-8769 |

| 1-1/4 | 3 | 1 | 660-8770 |

| 1-1/2 | 3 | 1 | 660-8771 |

| 1-3/4 | 3 | 1 | 660-8772 |

| 2 | 3 | 1 | 660-8773 |

| 3 | 3 | 1 | 660-8774 |

| 3-1/2 | 3-1/2 | 1 | 660-8775 |

| 4 | 3-1/2 | 1 | 660-8776 |

| 4-1/2 | 3-1/2 | 1 | 660-8777 |

| 5 | 3-1/2 | 1 | 660-8778 |

| 6 | 3-3/4 | 1-1/4 | 660-8779 |

| Module Pitch | Cutter Dia. | Sekoti sa boholo | 8pcs/sete |

| 0.5 | 2-1/2 | 1 | 660-8780 |

| 0.75 | 2-3/4 | 1 | 660-8781 |

| 1 | 3 | 1 | 660-8782 |

| 1-1/4 | 3 | 1 | 660-8783 |

| 1-1/2 | 3 | 1 | 660-8784 |

| 1-3/4 | 3 | 1 | 660-8785 |

| 2 | 3 | 1 | 660-8786 |

| 3 | 3 | 1 | 660-8787 |

| 3-1/2 | 3-1/2 | 1 | 660-8788 |

| 4 | 3-1/2 | 1 | 660-8789 |

| 4-1/2 | 3-1/2 | 1 | 660-8790 |

| 5 | 3-1/2 | 1 | 660-8791 |

| 6 | 3-3/4 | 1-1/4 | 660-8792 |

Kopo

Mesebetsi ea Spline Cutter:

Keyway milling cutter ke sesebelisoa sa ho itšeha se sebelisetsoang ho etsa machining ho hlahisa libopeho tse fapaneng tsa keyways le li-slots holim'a lisebelisoa tsa mosebetsi. E sebelisoa hangata liindastering tse kang ho etsa likoloi, sefofane le boenjiniere ba mechini.

Mosebetsi o ka sehloohong oa seha sekontiri sa keyway ke ho seha li-keyways le li-slots holim'a lisebelisoa, ho li fa libopeho le boholo bo itseng. Sesebelisoa sena sa ho itšeha se khona ho etsa ka nepo libopeho tse rarahaneng tsa keyway, ho fihlela litlhoko tse fapaneng ka mokhoa o itseng. Keyway milling cutter e bapala karolo ea bohlokoa molemong oa ho etsa machining, ho ntlafatsa katleho ea tlhahiso le boleng ba sehlahisoa.

Tšebeliso ea Spline Cutter:

Pele o sebelisa sehahi sa keyway milling, basebelisi ba tlameha ho etsa litokisetso tse latelang:

1. Workpiece Fixation: Ka tsela e sireletsehileng fasten workpiece tafoleng ea machining ho thibela ho sisinyeha kapa ho sisinyeha nakong ea machining.

2. Beha Mechini ea Mechini: Khetha lebelo le nepahetseng la ho itšeha, sekhahla sa phepelo, le botebo ba sehiloeng ho ipapisitse le lisebelisoa tsa mosebetsi le litlhoko tsa machining.

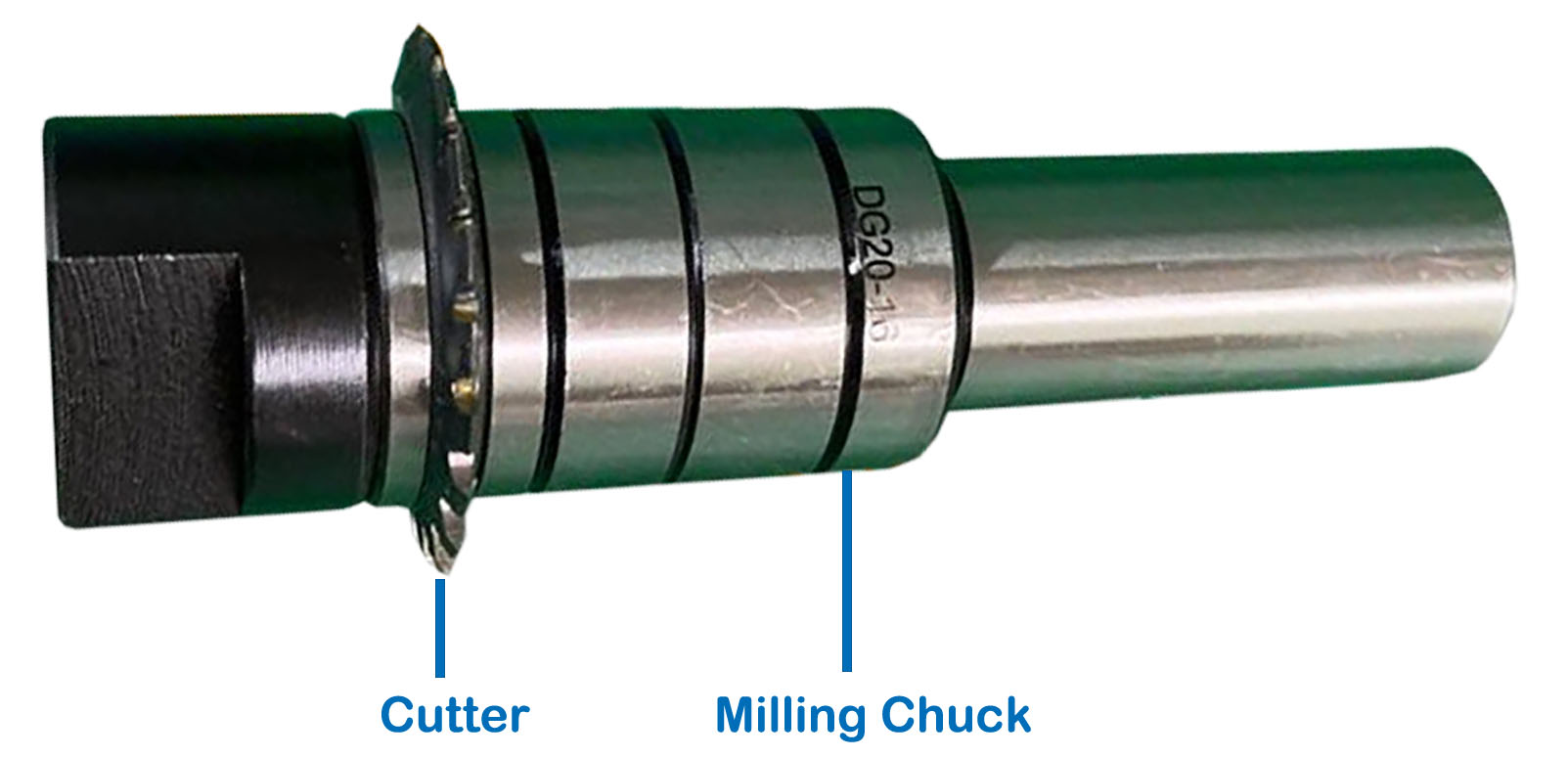

3. Kenya Keyway Milling Cutter: Beha mochini o silang oa keyway holim'a spindle ea mochini o silang kapa setsing sa machining, ho etsa bonnete ba hore lisebelisoa li tlamahanngoa le ho lokisoa.

Nakong ea machining, basebetsi ba lokela ho ela hloko tse latelang:

1. Etsa bonnete ba Tšireletseho: Boloka sebaka sa mosebetsi se sireletsehileng ka ho roala lisebelisoa tse loketseng tsa tšireletso le ho khomarela mekhoa ea tšireletso ho thibela likotsi.

2. Control Machining Parameters: Fetola mekhoa ea ho itšeha ka potlako ho ea ka maemo a machining ho etsa bonnete ba hore mekhoa ea ho itšeha e boreleli, ho qoba tšenyo ea lisebelisoa kapa boleng bo bobe ba workpiece.

3. Hlahloba Boleng ba ho sebetsa ha mochini: Kamehla hlahloba boleng ba holim'a mochini ho netefatsa hore litekanyo le libopeho tsa keyways le slots li finyella litlhoko. Fetola maemo a machining hanghang ho boloka boleng ba machining.

Litlhokomelo bakeng sa Spline Cutter:

1. Ha u sebelisa mochini oa ho sila ka keyway, ho lokela ho lebisoa tlhokomelo ho lintlha tse latelang:

2. Khetho ea Lisebelisoa: Khetha seha se nepahetseng sa keyway milling se ipapisitseng le lisebelisoa tsa mosebetsi le litlhoko tsa machining ho netefatsa ho itšeha hantle le ho sebetsa ka boleng bo holimo.

3. Tlhokomelo ea Lisebelisoa: Nako le nako hlahloba le ho boloka mochini oa ho sila oa linotlolo, ho kenyelletsa ho hloekisa, ho lokisa lisebelisuoa tse senyehileng, le ho kenya lithulusi tse senyehileng haholo hang-hang, ho etsa bonnete ba hore lisebelisoa li phela nako e telele le ho sebetsa ka nepo.

4. Tšebeliso ea Sepholi: Sebelisa sepholi se lekaneng nakong ea ho lokisa bakeng sa merero ea ho pholisa le ho tlotsa ho fokotsa mocheso oa ho itšeha, ho lelefatsa bophelo ba lisebelisoa, le ho tlosa li-cutting chips ka katleho.

Molemo

Tshebeletso e Sebetsang hantle le e Tshepehang

Lisebelisoa tsa Wayleading, morekisi oa hau oa sebaka se le seng bakeng sa lisebelisoa tsa ho seha, lisebelisoa tsa mochini, lisebelisoa tsa ho lekanya. Joalo ka setsi se kopaneng sa matla a indasteri, re motlotlo haholo ka Ts'ebeletso ea rona e Sebetsang le e Tšepahalang, e etselitsoeng ho fihlela litlhoko tse fapaneng tsa bareki ba rona ba hlomphuoang. Tobetsa Mona Bakeng sa Tse ling

Boleng bo Botle

Ho Lisebelisoa tsa Wayleading, boitlamo ba rona ba Boleng bo Botle bo re khetholla re le matla a maholo indastering. Joaloka setsi sa motlakase se kopantsoeng, re fana ka mefuta e fapaneng ea litharollo tsa indasteri tse tsoetseng pele, tse u fang lisebelisoa tse ntlehali tsa ho itšeha, lisebelisoa tse nepahetseng tsa ho lekanya, le lisebelisoa tse tšepahalang tsa mochini.TobetsaMona Bakeng sa Tse ling

Litheko tsa tlhōlisano

Rea u amohela ho Wayleading Tools, morekisi oa hau o le mong bakeng sa lisebelisoa tsa ho itšeha, lisebelisoa tsa ho lekanya, lisebelisoa tsa mochini. Re motlotlo haholo ka ho fana ka Litheko tsa Tlholisano e le o mong oa melemo ea rona ea mantlha.Tobetsa Mona Bakeng sa Tse ling

OEM, ODM, OBM

Ho Lisebelisoa tsa Wayleading, re motlotlo ka ho fana ka lits'ebeletso tse felletseng tsa OEM (Moetsi oa Lisebelisoa tsa Original), ODM (Original Design Manufacturer), le OBM (Own Brand Manufacturer), tse fanang ka litlhoko le mehopolo ea hau e ikhethang.Tobetsa Mona Bakeng sa Tse ling

Mefuta e sa tšoaneng e Atolositsoeng

Rea u amohela ho Wayleading Tools, sebaka seo u eang ho sona bakeng sa litharollo tsa morao-rao tsa indasteri, moo re ipabolang ka ho seha lisebelisoa, lisebelisoa tsa ho metha, le lisebelisoa tsa mochini. Monyetla oa rona oa mantlha ke ho fana ka mefuta e mengata e fapaneng ea lihlahisoa, tse etselitsoeng ho fihlela litlhoko tse fapaneng tsa bareki ba rona ba hlomphuoang.Tobetsa Mona Bakeng sa Tse ling

Lintho tse Tšoanang

Sekhechana se Kopantsoeng:DP Gear Cutter, Sehahi sa Mojule oa Gear

E lumellana le Arbor: Milling Machine Arbor

Tharollo

Tšehetso ea tekheniki:

Re thabetse ho ba mofani oa hau oa tharollo bakeng sa ER collet. Re thabela ho u fa tšehetso ea tekheniki. Ebang ke nakong ea thekiso ea hau kapa ts'ebeliso ea bareki ba hau, ha re fumana lipotso tsa hau tsa tekheniki, re tla araba lipotso tsa hau hanghang. Re tšepisa ho araba nakong ea lihora tse 24 haufinyane, re u fa litharollo tsa tekheniki.Tobetsa Mona Bakeng sa Tse ling

Litšebeletso tse ikhethileng:

Re thabela ho u fa lits'ebeletso tse ikhethileng tsa ER collet. Re ka fana ka litšebeletso tsa OEM, lihlahisoa tsa tlhahiso ho latela litšoantšo tsa hau; Litšebeletso tsa OBM, ho hlahisa lihlahisoa tsa rona ka letšoao la hau; le lits'ebeletso tsa ODM, ho fetola lihlahisoa tsa rona ho latela litlhoko tsa moralo oa hau. Ho sa tsotellehe hore na u hloka litšebeletso life, re tšepisa ho u fa litharollo tsa profeshenale.Tobetsa Mona Bakeng sa Tse ling

Litšebeletso tsa Koetliso:

Hore na o moreki oa lihlahisoa tsa rona kapa o mosebelisi oa ho qetela, re thabela ho fana ka ts'ebeletso ea koetliso ho netefatsa hore o sebelisa lihlahisoa tseo o li rekileng ho rona ka nepo. Lisebelisoa tsa rona tsa koetliso li tla ka litokomane tsa elektroniki, livideo le liboka tsa marang-rang, tse u lumellang ho khetha khetho e loketseng ka ho fetisisa. Ho tloha kopo ea hau ea koetliso ho isa ho phano ea litharollo tsa koetliso, re ts'episa ho phethela ts'ebetso eohle nakong ea matsatsi a 3Tobetsa Mona Bakeng sa Tse ling

Tšebeletso ka mor'a thekiso:

Lihlahisoa tsa rona li tla le nako ea tšebeletso ea likhoeli tse 6 ka mor'a thekiso. Nakong ena, mathata leha e le afe a sa hlahisoang ka boomo a tla nkeloa sebaka kapa a lokisoe ntle ho tefo. Re fana ka ts'ehetso ea litšebeletso tsa bareki bosiu le motšehare, ho sebetsana le lipotso kapa litletlebo life kapa life, ho netefatsa hore u na le boiphihlelo bo monate ba ho reka.Tobetsa Mona Bakeng sa Tse ling

Moralo oa Tharollo:

Ka ho fana ka moralo oa sehlahisoa sa hau sa machining (kapa ho thusa ho theha litšoantšo tsa 3D haeba li le sieo), litlhaloso tsa thepa, le lintlha tsa mochini tse sebelisitsoeng, sehlopha sa rona sa sehlahisoa se tla hlophisa likhothaletso tse loketseng bakeng sa lisebelisoa tsa ho seha, lisebelisoa tsa mochini le lisebelisoa tsa ho lekanya, le ho rala litharollo tse felletseng tsa machining. molemong oa hau.Tobetsa Mona Bakeng sa Tse ling

Ho paka

E phuthetsoe ka lebokoseng la polasetiki ka mokotla oa ho fokotsa mocheso. Ebe e kenngoa ka lebokoseng le ka ntle. E ka thijoa hantle hore e se ke ea rusa.

Hape ho phutheloa ka mokhoa o ikhethileng ho amoheloa.

● A na u hloka OEM, OBM, ODM kapa neutral packing bakeng sa lihlahisoa tsa hau?

● Lebitso la k'hamphani ea hau le lintlha tsa puisano bakeng sa maikutlo a potlakileng le a nepahetseng.

Ho feta moo, re u mema hore u kope mehlala ea tlhahlobo ea boleng.