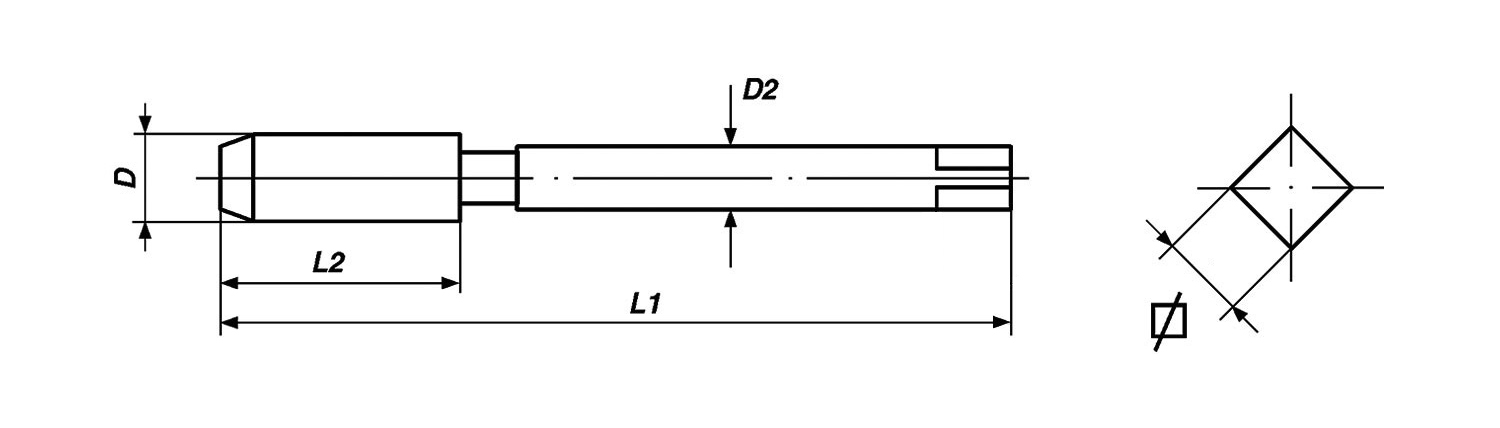

HSS DIN371 Tuubada Xadhkaha leh ee Tooska ah iyo Dhuxul-wareega ah

Tilmaamid

Magaca Alaabta: DIN371 Tuubada Mashiinka

Xagalka dunta: 60°

Flute: Toosan/Bool dhibic/Fluut wareeg ah oo degdeg ah 35º/ Qunyar qunyar socod 15º

Waxyaabaha: HSS/HSCo5%

Dahaarka: Bright/TiN/TiCN

Fuul toosan

| QAYBKA (D) | THREAD DHEERKA (L2) | Wadarta DHEERKA (L1) | SHANK DIA.(D2) | BARIGA (a) | HSS | HSCo5% | ||

| Iftiimin | TiN | Iftiimin | TiN | |||||

| M2×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3818 | 660-3831 | 660-3857 | 660-3870 |

| M2.3×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3819 | 660-3832 | 660-3858 | 660-3871 |

| M2.5×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3820 | 660-3833 | 660-3859 | 660-3872 |

| M2.6×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3821 | 660-3834 | 660-3860 | 660-3873 |

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-3822 | 660-3835 | 660-3861 | 660-3874 |

| M3.5×0.6 | 12 | 56 | 4 | 3 | 660-3823 | 660-3836 | 660-3862 | 660-3875 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-3824 | 660-3837 | 660-3863 | 660-3876 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-3825 | 660-3838 | 660-3864 | 660-3877 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-3826 | 660-3839 | 660-3865 | 660-3878 |

| M7×1 | 17 | 80 | 7 | 5.5 | 660-3827 | 660-3840 | 660-3866 | 660-3879 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-3828 | 660-3841 | 660-3867 | 660-3880 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-3829 | 660-3842 | 660-3868 | 660-3881 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-3830 | 660-3843 | 660-3869 | 660-3882 |

Barta Spiral

| QAYBKA (D) | THREAD DHEERKA (L2) | Wadarta DHEERKA (L1) | SHANK DIA.(D2) | BARIGA (a) | HSS | HSCo5% | ||

| Iftiimin | TiN | Iftiimin | TiN | |||||

| M2×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3896 | 660-3909 | 660-3935 | 660-3948 |

| M2.3×0.4 | 7 | 45 | 2.8 | 2.1 | 660-3897 | 660-3910 | 660-3936 | 660-3949 |

| M2.5×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3898 | 660-3911 | 660-3937 | 660-3950 |

| M2.6×0.45 | 9 | 50 | 2.8 | 2.1 | 660-3899 | 660-3912 | 660-3938 | 660-3951 |

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-3900 | 660-3913 | 660-3939 | 660-3952 |

| M3.5×0.6 | 12 | 56 | 4 | 3 | 660-3901 | 660-3914 | 660-3940 | 660-3953 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-3902 | 660-3915 | 660-3941 | 660-3954 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-3903 | 660-3916 | 660-3942 | 660-3955 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-3904 | 660-3917 | 660-3943 | 660-3956 |

| M7×1 | 17 | 80 | 7 | 5.5 | 660-3905 | 660-3918 | 660-3944 | 660-3957 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-3906 | 660-3919 | 660-3945 | 660-3958 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-3907 | 660-3920 | 660-3946 | 660-3959 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-3908 | 660-3921 | 660-3947 | 660-3960 |

Fluut Spiral Degdega ah 35º

| QAYBKA (D) | THREAD DHEERKA (L2) | Wadarta DHEERKA (L1) | SHANK DIA.(D2) | BARIGA (a) | HSS | HSCo5% | ||

| Iftiimin | TiN | Iftiimin | TiN | |||||

| M3×0.5 | 5 | 56 | 3.5 | 2.7 | 660-3974 | 660-3981 | 660-3995 | 660-4002 |

| M4×0.7 | 7 | 63 | 4.5 | 3.4 | 660-3975 | 660-3982 | 660-3996 | 660-4003 |

| M5×0.8 | 8 | 70 | 6 | 4.9 | 660-3976 | 660-3983 | 660-3997 | 660-4004 |

| M6×1 | 10 | 80 | 6 | 4.9 | 660-3977 | 660-3984 | 660-3998 | 660-4005 |

| M8×1.25 | 13 | 90 | 8 | 6.2 | 660-3978 | 660-3985 | 660-3999 | 660-4006 |

| M10×1.5 | 15 | 100 | 10 | 8 | 660-3979 | 660-3986 | 660-4000 | 660-4007 |

| M12×1.75 | 18 | 110 | 12 | 9 | 660-3980 | 660-3987 | 660-4001 | 660-4008 |

Slow spiral flulute 15º

| QAYBKA (D) | THREAD DHEERKA (L2) | Wadarta DHEERKA (L1) | SHANK DIA.(D2) | BARIGA (a) | HSS | HSCo5% | ||

| Iftiimin | TiN | Iftiimin | TiN | |||||

| M3×0.5 | 11 | 56 | 3.5 | 2.7 | 660-4016 | 660-4023 | 660-4037 | 660-4044 |

| M4×0.7 | 13 | 63 | 4.5 | 3.4 | 660-4017 | 660-4024 | 660-4038 | 660-4045 |

| M5×0.8 | 15 | 70 | 6 | 4.9 | 660-4018 | 660-4025 | 660-4039 | 660-4046 |

| M6×1 | 17 | 80 | 6 | 4.9 | 660-4019 | 660-4026 | 660-4040 | 660-4047 |

| M8×1.25 | 20 | 90 | 8 | 6.2 | 660-4020 | 660-4027 | 660-4041 | 660-4048 |

| M10×1.5 | 22 | 100 | 10 | 8 | 660-4021 | 660-4028 | 660-4042 | 660-4049 |

| M12×1.75 | 24 | 110 | 12 | 9 | 660-4022 | 660-4029 | 660-4043 | 660-4050 |

Flute Toosan DIN 371 Tuubada Mashiinka

Codsiga: Waxay ku habboon tahay dunta indho la'aanta ama daloolada birta, birta aan la taaban karin, birta shubka, iyo walxaha aan birta ahayn. Ilkaheeda dhulka ah iyo chamfer daboolaya 2-3 dun ayaa ka dhigaya mid ku habboon qoto dheer dunta in ka yar 2 jeer dhexroorka tuubada (2d1).

Isticmaalka lagu taliyay: Noocani si gaar ah ayuu wax ku ool u yahay garaacista gacanta sababtoo ah biibitaankiisa tooska ah, oo bixiya xasilooni iyo sahlan isticmaalka.

Spiral Point DIN 371 Tuubada Mashiinka

Codsiga: Waxaa loo qaabeeyey abuurista dunta godadka dhexdooda, tuubadani waxay ka kooban tahay ilko dhulka ah iyo maro 4-5 dun ah. Waxay wax ku ool u tahay moolka dunta ilaa 3 jeer dhexroorka tuubada (3d1) ee birta, birta aan fiicnayn, iyo birta shubka ah.

Isticmaalka lagu taliyay: Barta wareeggu waxay hore u riixdaa jajabyada, taas oo ka dhigaysa mid ku habboon in la maro godadka halkaas oo daadgureynta jajabku ay tahay mid toos ah.

Fluut Spiral Degdega ah 35º DIN 371 Tuubada Mashiinka

Codsiga: Tuubadaan waxaa loogu talagalay godad indho la'aan ah oo birta ah, birta aan birta lahayn, birta shubka ah, iyo walxaha aan birta ahayn ee leh dunta qoto dheer ilaa 2.5 jeer dhexroorka tuubada (2.5d1). 35º ee degdega ah ee flute spiral wuxuu caawiyaa daadgureyn hufan.

Isticmaalka lagu taliyay: Ku habboon mashiinnada CNC halkaas oo dunta xawaaraha sare leh iyo saxnaanta ay muhiim tahay.

Slow Spiral Flute 15º DIN 371 Tuubada Mashiinka

Codsiga: Si la mid ah u dhiggiisa xawaaraha dheereeya, tuubadaan waxaa loo isticmaalaa godadka indha la'aanta ee alaabta la midka ah, laakiin leh xadka qoto dheer ee 2 jeer dhexroorka tuubada (2d1). 15º biibiile tartiib tartiib ah wuxuu bixiyaa ka saarista jajabka la xakameeyey.

Isticmaalka lagu taliyay: Waxaa lagu taliyay agabka soo saara jajabyo dhaadheer oo adag, hubinta habka dunta nadiifka ah.

Xulashada dahaarka

Iftiimin, TiN (Titanium Nitride), TiCN (Titanium Carbonitride): Dahaarkani waxay kor u qaadaan adkaysiga tuubada, caabbinta kulaylka, iyo lubricity, taas oo kordhinaysa nolosha qalabka iyo waxqabadka agabyada kala duwan.

Mid kasta oo ka mid ah qasabadahan ayaa si gaar ah loogu habayn karaa si loogu isticmaalo goobaha mishiinada ee kala duwan, iyadoo ku xidhan walxaha, nooca daloolka, iyo qoto dheeraanta dunta la doonayo. Waa muhiim in la doorto nooca saxda ah ee tuubada mashiinka DIN 371 codsi kasta si loo hubiyo waxqabadka ugu fiican iyo cimriga qalabka.

Faa'iidada Wayleading

Adeeg hufan oo la isku hallayn karo;

• Tayo Wanaagsan;

• Qiimaha tartanka;

• OEM, ODM, OBM;

• Kala duwanaansho Balaadhan

• Degdega & Gaarsiinta lagu kalsoonaan karo

Nuxurka Xidhmada

1 x DIN371 Tuubada Mashiinka

1 x Kiiska Ilaalinta

Ma u baahan tahay OEM, OBM, ODM ama baakad dhexdhexaad ah alaabtaada?

● Magaca shirkaddaada iyo macluumaadka xiriirka si aad u hesho jawaab celin degdeg ah oo sax ah.

Intaa waxaa dheer, waxaan kugu martiqaadeynaa inaad codsato muunado si loo tijaabiyo tayada.