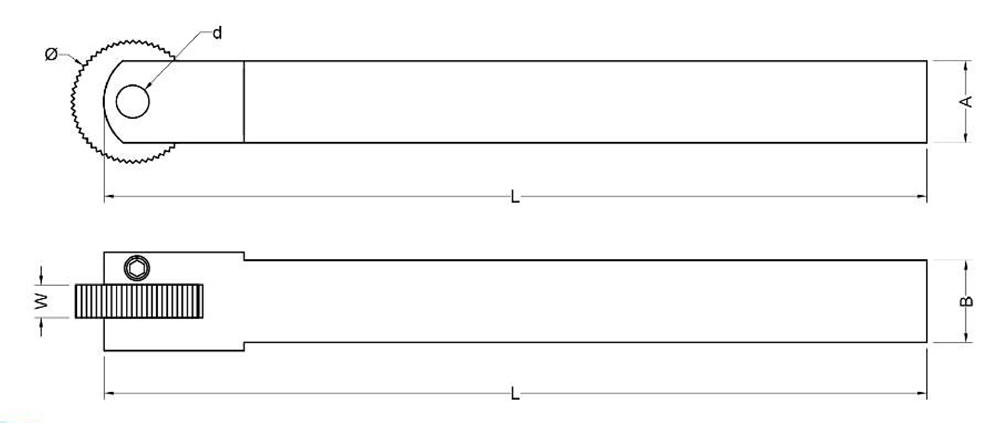

Single Wheel Knurling Tools With Straight Pattern For Industrial Type

Single Wheel Knurling Tools

● Complete with medium cut HSS Or 9SiCr knurl best sutied for shorter work

● Holder size: 21x18mm

● Pitch: From 0.4 to 2mm

● Length: 112mm

● Pitch: From 0.4 to 2mm

● Wheel Dia.: 28mm

● For Straight Pattern

| Pitch | Alloy Steel | HSS |

| 0.4 | 660-7892 | 660-7901 |

| 0.5 | 660-7893 | 660-7902 |

| 0.6 | 660-7894 | 660-7903 |

| 0.8 | 660-7895 | 660-7904 |

| 1.0 | 660-7896 | 660-7905 |

| 1.2 | 660-7897 | 660-7906 |

| 1.6 | 660-7898 | 660-7907 |

| 1.8 | 660-7899 | 660-7908 |

| 2.0 | 660-7900 | 660-7909 |

Enhancing Grip and Aesthetics

Wheel knurling tools are essential in the realm of metalworking, primarily used to impart a distinctive textured pattern onto the surface of metal rods and cylindrical objects. Their primary function is to increase the tactile grip and enhance the aesthetic appeal of the finished products.

Practical Applications in Automotive and Aerospace

The process of knurling, executed by these tools, involves the pressing of a pattern onto the surface of a smooth metal rod. As the tool rolls over the metal, it deforms the surface to create a consistent, raised pattern. This pattern significantly increases the friction between the metal object and the hand holding it. In practical terms, this enhanced grip is crucial for components that are often handled, such as tool handles, levers, and custom-made metal parts that require manual adjustment or operation.

Aesthetic Appeal in Consumer Goods

In industries where safety and precision handling are paramount, such as in automotive and aerospace manufacturing, wheel knurling tools are invaluable. For example, in automotive applications, they are used to create non-slip surfaces on gear levers and control knobs. This ensures a secure grip for the driver, even under conditions where moisture or grease might be present. Similarly, in aerospace, the knobs and controls in the cockpit benefit from knurling, providing pilots with a firm grip, which is essential for precise control.

Beyond their functional benefits, wheel knurling tools also contribute to the aesthetic quality of metal parts. The textured patterns created are not only practical but also visually appealing. They add a level of sophistication and style to the product, which can be particularly important in consumer goods where the appearance of the product is a significant factor in consumer choice. For instance, in the production of high-end audio equipment, camera bodies, and even in custom motorcycle parts, the knurled texture provides both a functional advantage and a distinctive visual appeal.

Artistic Use in Custom Fabrication

Custom fabrication and metal artwork are other areas where wheel knurling tools find significant use. In these domains, the texture and pattern created by the knurling process are used to add intricate details and decorative elements to metal pieces. The ability of these tools to work with various metals and to produce different patterns allows for a wide range of creative applications, from bespoke jewelry pieces to unique architectural features.

Educational Value in Metalworking

In addition to their use in manufacturing and custom fabrication, wheel knurling tools are also an important tool in educational settings. Technical schools and vocational training centers often use these tools to teach students about surface treatments and finishes in metalworking. They provide a hands-on experience of how to manipulate metal surfaces for both functional and aesthetic purposes.

Restoration in Repair and Maintenance

Moreover, in the realm of repair and maintenance, knurling tools are used to refurbish old or worn-out metal parts. They can rejuvenate the grip on tool handles or mechanical levers, extending the life of these tools and enhancing their usability.

Wheel knurling tools are versatile instruments in the metalworking industry, valued for their ability to enhance both the functionality and aesthetics of metal products. From industrial applications to artisanal craftsmanship, they play a crucial role in adding both practicality and artistic flair to metal objects.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Single Wheel Knurling Tool

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.