Precision Dial Test Indicator Gage For Industrial

Dial Test Indicator

● A hard frame body providing excellent rigidity.

● White edge of dial for easy to read.

● Hardened and fround contact point.

● Satin chrome-finish case for durability.

● Precision gear-driven design with smooth movement.

| Range | Graduation | Dia. Size | Order No. |

| 0-8mm | 0.01mm | 32mm | 860-0882 |

| 0-8mm | 0.01mm | 32mm | 860-0883 |

| 0-3" | 0.0005" | 40mm | 860-0884 |

| 0-3" | 0.0005" | 40mm | 860-0885 |

Precision Measurement in Manufacturing

The Dial Test Indicator finds extensive use in manufacturing processes, particularly in the measurement of small distances and deviations. Whether it’s aligning components during assembly or checking the concentricity of machined parts, the DTI’s sensitivity and accuracy make it an indispensable tool for maintaining tight tolerances in production.

Runout and TIR Measurement

One of the primary applications of the Dial Test Indicator is the measurement of runout and Total Indicator Reading (TIR). In machining, the DTI aids machinists in assessing the radial and axial movement of rotating components, ensuring that parts meet the specified tolerances and minimizing deviations that could affect performance.

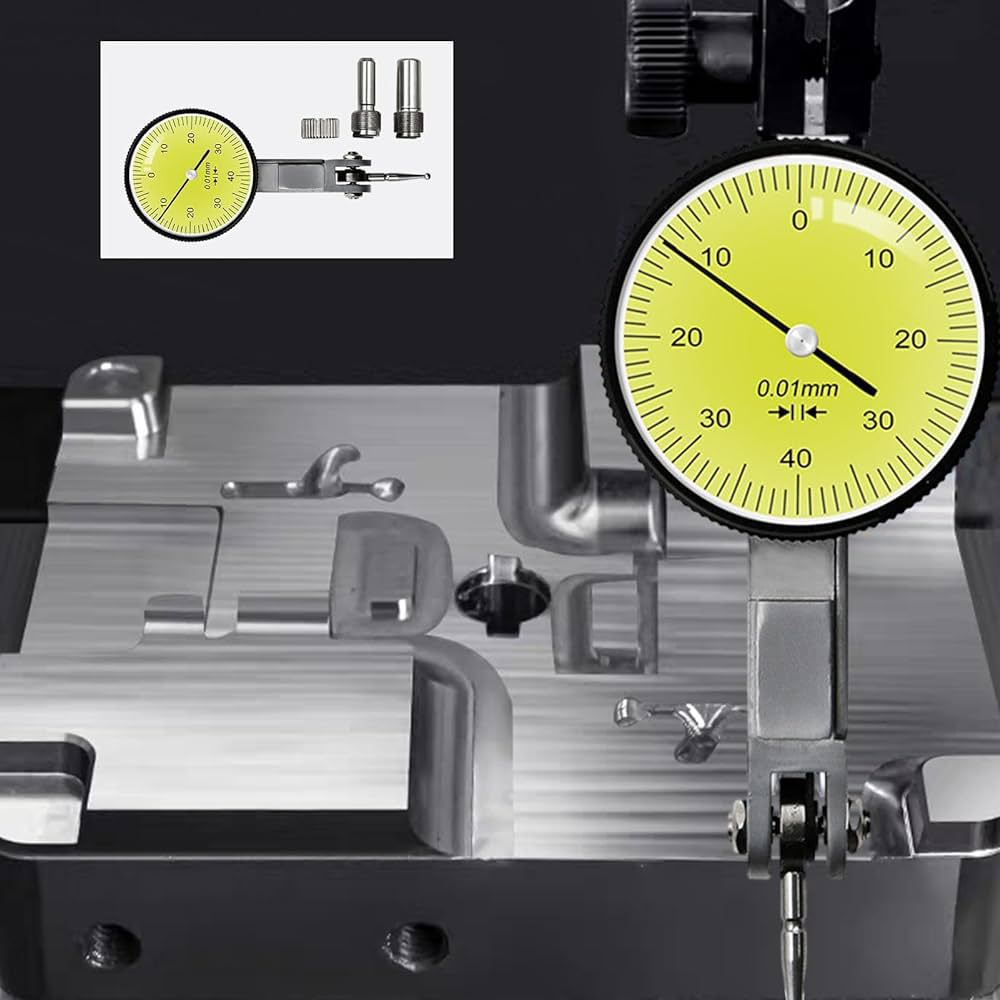

Tool Setting and Calibration

In tool and die manufacturing, the Dial Test Indicator is employed for tool setting and calibration. Machinists use it to align cutting tools with precision, ensuring that tools are properly set for accurate and efficient machining operations. This application is critical for achieving high-quality finished products.

Surface Flatness and Straightness

The DTI is also utilized in measuring surface flatness and straightness. By carefully traversing the indicator across a surface, machinists can detect any irregularities or deviations, allowing them to correct issues and maintain the desired flatness or straightness in machined components.

Quality Control in Aerospace

In the aerospace industry, where stringent quality standards prevail, the Dial Test Indicator serves as a key tool for quality control inspections. Its ability to detect minute variations in dimensions ensures that critical components, such as aircraft engine parts, adhere to the strict specifications required for safety and performance.

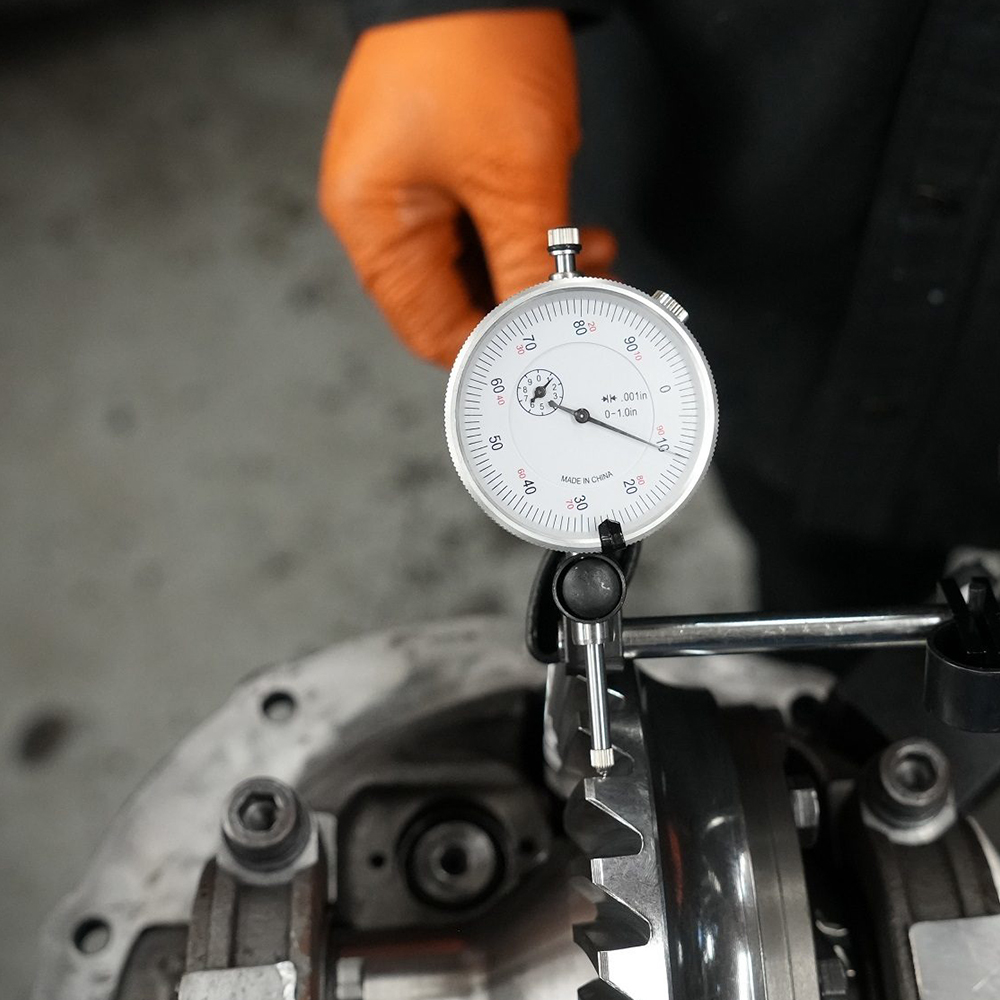

Automotive Precision Engineering

In automotive manufacturing, precision is paramount, and the DTI plays a crucial role in achieving the required accuracy. Whether it’s checking the alignment of engine components or ensuring proper clearances, the DTI contributes to the precision engineering that underlies the safety and functionality of vehicles.

Versatility and Ease of Use

The Dial Test Indicator’s versatility lies in its adaptability to various measurement tasks. Equipped with a swiveling bezel and fine-tuning controls, machinists can easily set and adjust the indicator for different applications. Its user-friendly design makes it a go-to tool for machinists seeking efficient and accurate measurements.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x dial Test Indicator

1 x Protective Case

1 x Inspection Certificate

Please contact us for further information. To assist you more effectively, Kindly provide the following details:

● Specific product models and the approximate quantities you require.

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.