MT/R8 Shank Quick Change Tapping Chuck With MT & R8 Shank

Quick Change Tapping Chuck

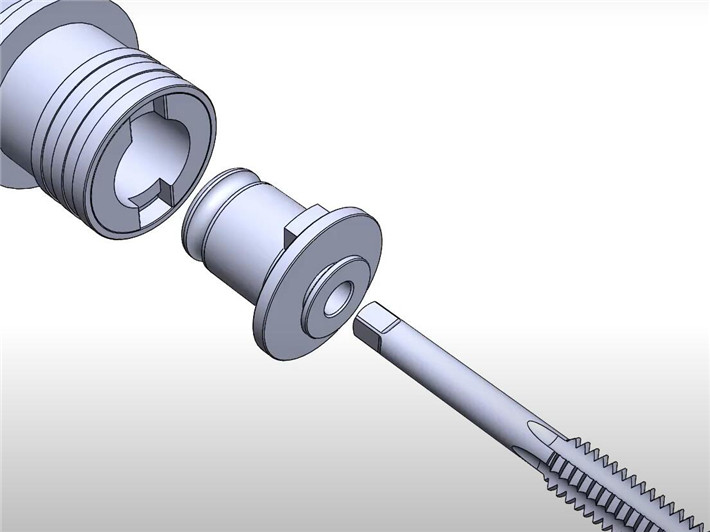

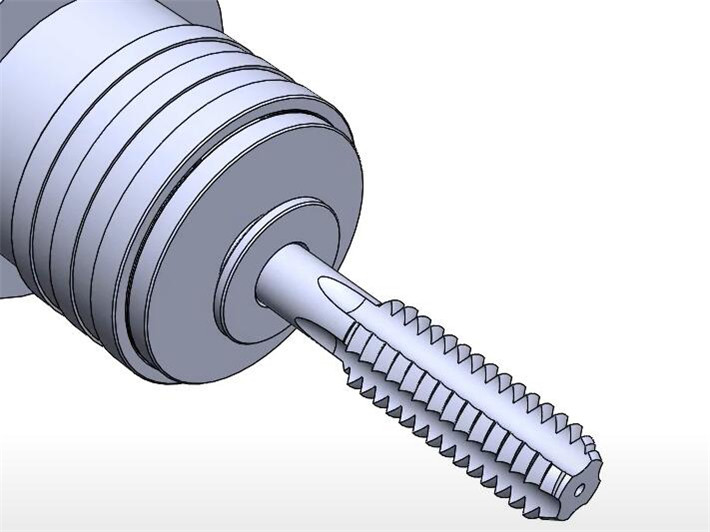

● The fast-changing device on the front of the tap can be automatically locked so as to improve efficiency.

● The internal automatic compensation mechanism can eliminate the feeding error and is applicable to the tapping of many heads at the same time.

● The connecting structure of the chuck is the fast-changing structure, which enables the fast changing taps and chucks to improve efficiency.

● The overload protective device inside the chuck can adjust the torque to prevent the tap from being damaged.

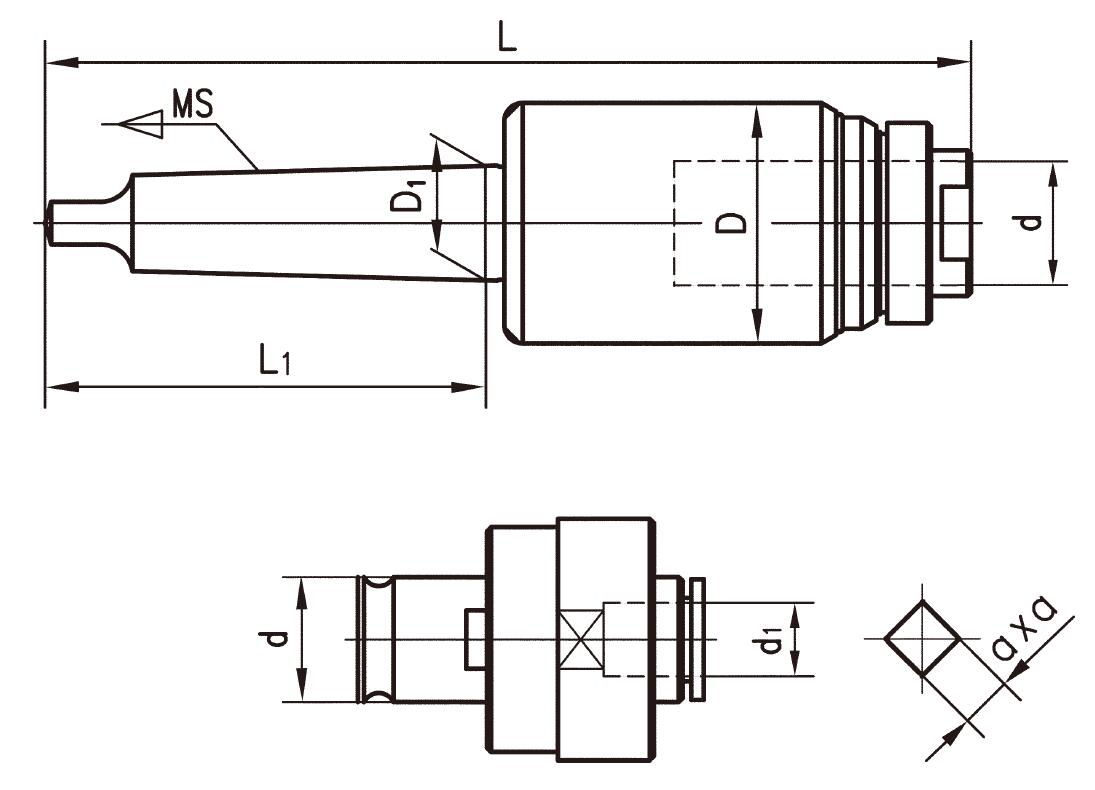

| Size | Shank | Max Torque(Nm) | D | d | L1 | L | Order No. |

| M3-M12 | MT2 | 25 | 46 | 19 | 75 | 171.5 | 660-8626 |

| M3-M12 | MT3 | 25 | 46 | 19 | 94 | 191 | 660-8627 |

| M3-M12 | MT4 | 25 | 46 | 19 | 117.5 | 216 | 660-8628 |

| M3-M16 | R8 | 46.3 | 46 | 19 | 101.6 | 193.6 | 660-8629 |

| M3-M16 | MT2 | 46.3 | 46 | 19 | 75 | 171.5 | 660-8630 |

| M3-M16 | MT3 | 46.3 | 46 | 19 | 94 | 191 | 660-8631 |

| M3-M16 | MT4 | 46.3 | 46 | 19 | 117.5 | 216 | 660-8632 |

| M12-M24 | MT3 | 150 | 66 | 30 | 94 | 227 | 660-8633 |

| M12-M24 | MT4 | 150 | 66 | 30 | 117.5 | 252 | 660-8634 |

| M12-M24 | MT5 | 150 | 66 | 30 | 149.5 | 284 | 660-8635 |

| Tapping range | M3 | M4 |

| d1xa(mm) | 2.24X1.8 | 3.15X2.5 |

| M5 | M6 | M8 | M10 | M12 |

| 4X3.15 | 4.5X3.55 | 6.3X5 | 8X6.3 | 9X7.1 |

| Tapping range | M14 | M16 |

| d1xa(mm) | 11.2X9 | 12.5X10 |

| M18 | M20 | M22 | M24 |

| 14X11.2 | 14X11.2 | 16X12.5 | 18X14 |

Versatility and Precision in Machining

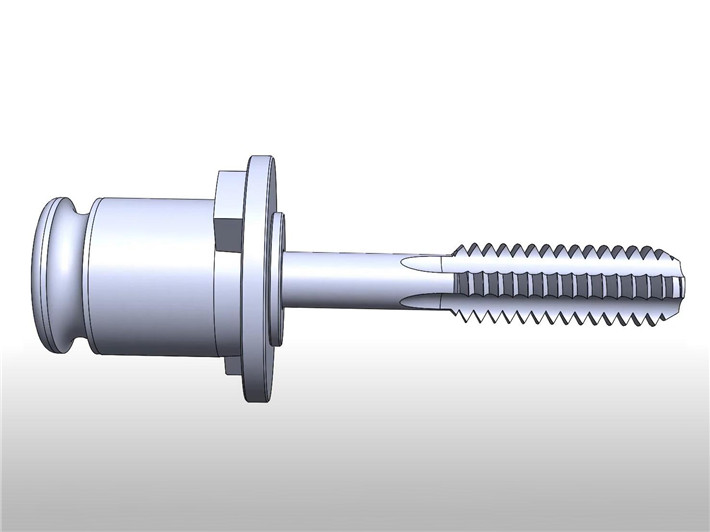

The Quick Change Tapping Chuck, with its unique combination of a main body and a tap chuck, has become an indispensable tool in modern machining operations. In the realm of precision metalworking, this chuck plays a pivotal role. Its forward and reverse pitch compensation feature in the main body allows for precise threading, essential in creating accurate and consistent screw threads in components. This precision is vital in industries such as aerospace and automotive, where even the slightest deviation can lead to significant consequences.

Versatility and Precision in Machining

Moreover, the tap chuck’s torque overload protection is a game-changer in preventing tap breakage, a common issue in threading operations. This feature is particularly beneficial when working with hard metals or in high-volume production environments where the wear and tear on tools are significant. By safeguarding against breakage, the Quick Change Tapping Chuck ensures continuity in production and reduces downtime, resulting in increased efficiency and cost savings.

Versatility and Precision in Machining

The chuck’s ability to easily adjust to different sizes of taps by simply modifying the nut enhances its versatility. This adaptability makes it suitable for a wide range of applications, from small-scale precision engineering workshops to large manufacturing plants. The Quick Change Tapping Chuck is especially valuable in custom manufacturing setups, where the need for rapidly changing between different tap sizes is frequent.

Versatility and Precision in Machining

In educational settings, this chuck serves as an excellent tool for teaching students the intricacies of threading and tap handling. Its ease of use and safety features make it an ideal choice for instructional workshops in technical and vocational schools.

Versatility and Precision in Machining

For DIY enthusiasts and hobbyists, the Quick Change Tapping Chuck brings professional-level precision and efficiency to personal projects. Whether it’s creating custom parts, repairing machinery, or engaging in creative metalworking, this chuck provides the reliability and versatility needed for diverse applications.

The Quick Change Tapping Chuck’s innovative design, which combines pitch compensation and torque overload protection, along with its ease of adaptability, makes it a vital tool across various sectors, including precision metalworking, education, and DIY projects.

Versatility and Precision in Machining

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Versatility and Precision in Machining

1 x The Quick Change Tapping Chuck

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.