Typus M Cone Tungsten Carbide Gyratorius Burr

Typus M Cone Tungsten Carbide Gyratorius Burr

● Secat: Duplex, Duplex, Diamond, Alu Cuts

Coating: Num Coate per TiAlN

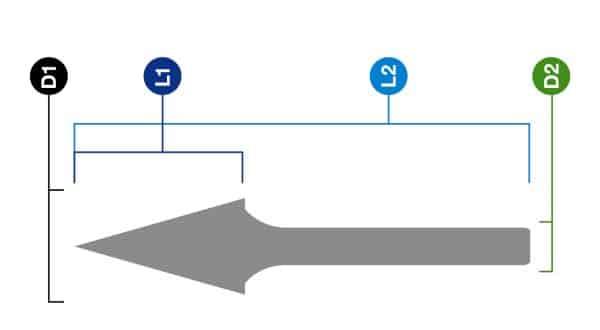

Metric

| Model | D1 | L1 | L2 | D2 | una Cut | Duplex Cut | Diamond Cut | Alu Cut |

| M0307 | 3 | 7 | 40 | 3 | 660-3118 | 660-3124 | 660-3130 | 660-3136 |

| M0311 | 3 | 11 | 40 | 3 | 660-3119 | 660-3125 | 660-3131 | 660-3137 |

| M0613 | 6 | 13 | 43 | 3 | 660-3120 | 660-3126 | 660-3132 | 660-3138 |

| M0618 | 6 | 18 | 50 | 6 | 660-3121 | 660-3127 | 660-3133 | 660-3139 |

| M1020 | 10 | 20 | 60 | 6 | 660-3122 | 660-3128 | 660-3134 | 660-3140 |

| M1225 | 12 | 25 | 65 | 6 | 660-3123 | 660-3129 | 660-3135 | 660-3141 |

Inch

| Model | D1 | L1 | L2 | D2 | una Cut | Duplex Cut | Diamond Cut | Alu Cut |

| SM-1 | 1/4" | 1/2" | 22º | 1/4" | 660-3554 | 660-3560 | 660-3566 | 660-3572 |

| SM-2 | 1/4" | 3/4" | 14º | 1/4" | 660-3555 | 660-3561 | 660-3567 | 660-3573 |

| SM-3 | 1/4" | 1" | 10º | 1/4" | 660-3556 | 660-3562 | 660-3568 | 660-3574 |

| SM-4 | 3/8" | 5/8" | 28º | 1/4" | 660-3557 | 660-3563 | 660-3569 | 660-3575 |

| SM-5 | 1/2" | 7/8" | 28º | 1/4" | 660-3558 | 660-3564 | 660-3570 | 660-3576 |

| SM-6 | 5/8" | 1" | 31º | 1/4" | 660-3559 | 660-3565 | 660-3571 | 660-3577 |

Metal Fabricatio Deburring

Tungsten Carbide Rotary Burrs magni aestimantur in industria metallica ob eorum mobilitatem et eximiam observantiam in amplis muneribus. Horum instrumentorum usus primarios includunt.

Deburding et curatio welding: Isti lappas sunt egregiae in fabricatione metallica, maxime efficax ad tollendum lappas ex glutino vel incisione provenientes.

Subtilitas Shaping et Sculptura

Eorum durities superior et resistentia induunt ea instrumenta idealia ad operationes accuratas et accuratas deburendas.

Fingens et Sculptura: Nota subtiliter in partibus metallis effingendis, insculpendis, et torulo, Tungsten Carbide Rotary Burrs excellunt in operandis variis metallis, inclusis sed non limitibus ad mixturas durissimas et aluminium.

Molendum et poliendo Efficiency

Molere et polire: In agro praecisione metallorum, hae lappas necessariae sunt, praesertim ad stridorem et politionem operum. Eorum notabilis duritia et diuturna durabilitas in his locis functionem suam augent.

Reaming et Edging Adjustments

Reaming et Edging: Tungsten Carbide Rotary Burrs saepe instrumenta electionis sunt aptandi vel augendi dimensiones et Venustates existendi foramina in processibus mechanicis producendi.

Superficiem Purgatio

Castings purgatio: In industria dejectiones, hi lappa magnum munus habent in materia excessus abjectionibus removendis et qualitatem superficiei augendae.

Eorum late exsecutionem in variis industriis, ut fabricandis, automotives reparandis, metallis artibus, et aerospace, acutis efficaciam et aptam naturam Tungsteni Carbide Rotary Burrs comprehendit.

Utilitas Wayleading

• Efficiens and Reliable Service;

• Bonitas;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Varietas

• Fast & PRAEIUDICATUS Delivery

Sarcina Content

1 x Typus M Cone Tungsten Carbide Rotary Burr

1 x Casus Protective

Rogas OEM, OBM, ODM vel neutram sarcinam pro tuis productis?

● Societas tua nomen et contactum informationes pro prompta et accurata feedback.

Additional, te invitamus ut exempla pro qualitate probationis petamus.