Auto Self Reversible Tapping Chuck In Drill Machine

Auto Self Reversing Tapping Head

● Use with Jacobs or threaded mounts adapters on manual operated drilling and milling machine for self reversing tapping heads.

● The adjustable torque prevents damage and tap breakage for self reversing tapping heads.

● High ratio of reaverse turing speed improves productivity for self reversing tapping heads.

● Easy operation design for reversing type tapping heads for self reversing tapping heads.

● Rubber flexible collets for reversing type tapping heads.

| Capacity of Metric Thread (In Steel) |

Capacity of Inch Thread (In Steel) |

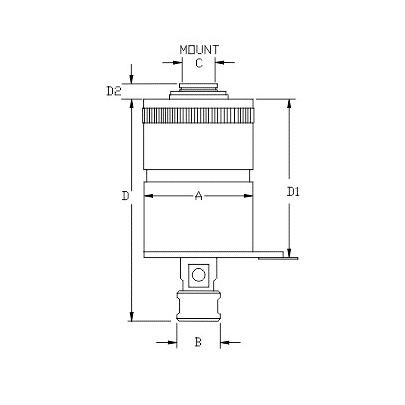

Dimensions(mm) | |||||||

| Mounts | D | D1 | D2 | A | B | C | Order No. | ||

| M1.4-M7 | #0-1/4" | JT6 | 124 | 88 | 11 | 52 | 23 | 22.5 | 210-0210 |

| M1.4-M7 | #0-1/4" | JT33 | 124 | 88 | 11 | 52 | 23 | 22.5 | 210-0211 |

| M1.4-M7 | #0-1/4" | 5/16"-24 | 124 | 88 | 11 | 52 | 23 | 22.5 | 210-0212 |

| M1.4-M7 | #0-1/4" | 3/8"-24 | 124 | 88 | 11 | 52 | 23 | 22.5 | 210-0213 |

| M1.4-M7 | #0-1/4" | 1/2"-20 | 124 | 88 | 11 | 52 | 23 | 22.5 | 210-0214 |

| M1.4-M7 | #0-1/4" | 5/8"-16 | 124 | 88 | 11 | 52 | 23 | 22.5 | 210-0215 |

| M3-M12 | #6-1/2" | JT6 | 155 | 110 | 9 | 74 | 28 | 28 | 210-0220 |

| M3-M12 | #6-1/2" | JT33 | 155 | 110 | 9 | 74 | 28 | 28 | 210-0221 |

| M3-M12 | #6-1/2" | 1/2"-20 | 155 | 110 | 9 | 74 | 28 | 28 | 210-0222 |

| M3-M12 | #6-1/2" | 5/8"-16 | 155 | 110 | 9 | 74 | 28 | 28 | 210-0223 |

| M3-M12 | #6-1/2" | 3/4"-16 | 155 | 110 | 9 | 74 | 28 | 28 | 210-0224 |

| M5-M20 | #10-3/4" | JT3 | 195 | 132 | 10 | 91 | 38 | 35.5 | 210-0230 |

| M5-M20 | #10-3/4" | 1/2"-20 | 195 | 132 | 10 | 91 | 38 | 35.5 | 210-0231 |

| M5-M20 | #10-3/4" | 5/8'-16 | 195 | 132 | 10 | 91 | 38 | 35.5 | 210-0232 |

| M5-M20 | #10-3/4" | 3/4"-16 | 195 | 132 | 10 | 91 | 38 | 35.5 | 210-0233 |

| Rubberflex Collets | |

| Size | Order No. |

| 4.2mm (2.0-4.2mm/.079-.165") | 210-0280 |

| 6.5mm (4.2-6.5mm/.165-.256") | 210-0282 |

| 7.0mm (3.5-7.0mm/,137-.275") | 210-0284 |

| 9.0mm (5.0-9.0mm/.196-.354") | 210-0286 |

| 10.0mm (7.0-10.0mm/.275-.393") | 210-0288 |

| 14.0mm (9.0-14.0mm/.354-.551") | 210-0290 |

Precision and Efficiency in Machining

The Auto Self Reversing Tapping Head, equipped with a host of innovative features, is a transformative tool in the realm of machining, particularly in operations that require precise tapping. With its compatibility for use with Jacobs or threaded mounts adapters, adjustable torque settings, high reverse turning speed ratio, easy operation design, and rubber flexible collets, it represents a significant leap in technology for manufacturers and machinists. The integration of a reversible tapping chuck into these heads has further enhanced their utility, making them indispensable in various industrial applications.

Minimizing Tap Breakage with Adjustable Torque

In the domain of precision machining, the Auto Self Reversing Tapping Head, coupled with a reversible tapping chuck, offers unparalleled accuracy and efficiency. This combination is particularly beneficial in industries where the integrity of threaded holes is paramount, such as aerospace, automotive, and medical device manufacturing. The adjustable torque feature minimizes the risk of tap breakage by ensuring that the applied force does not exceed the tap’s tolerance, thereby preventing damage to both the tap and the workpiece. This precision safeguards against costly manufacturing errors and downtime, ensuring that production lines run smoothly and efficiently.

Enhancing Productivity with High Reverse Speed

Moreover, the high ratio of reverse turning speed of these tapping heads drastically improves productivity. By enabling faster withdrawal of the tap from the workpiece, it significantly reduces cycle times, allowing for a greater volume of parts to be produced within the same timeframe. This speed efficiency is a critical factor in high-volume manufacturing environments where meeting production quotas within tight deadlines is essential.

User-Friendly Operation and Setup

The ease of operation of the Auto Self Reversing Tapping Head is another noteworthy feature. The user-friendly design of the reversible tapping chuck allows for quick and easy setup and adjustment, making it accessible to operators of varying skill levels. This ease of use is particularly advantageous in job shops and custom manufacturing settings, where the flexibility to quickly switch between different tapping tasks without extensive downtime is crucial.

User-Friendly Operation and Setup

The ease of operation of the Auto Self Reversing Tapping Head is another noteworthy feature. The user-friendly design of the reversible tapping chuck allows for quick and easy setup and adjustment, making it accessible to operators of varying skill levels. This ease of use is particularly advantageous in job shops and custom manufacturing settings, where the flexibility to quickly switch between different tapping tasks without extensive downtime is crucial. Additionally, the use of rubber flexible collets in these tapping heads offers significant advantages in terms of tool longevity and material compatibility. These collets provide a secure grip on the tap, reducing vibration and wear, which in turn extends the life of the tapping tools. This feature is especially beneficial when working with a wide range of materials, from soft plastics to hard metals, ensuring consistent performance and reliability across diverse applications.

Versatility and Durability with Rubber Collets

The application of the Auto Self Reversing Tapping Head, particularly when integrated with a reversible tapping chuck, spans across a broad spectrum of manufacturing and machining operations. From mass production facilities focused on automotive components to bespoke workshops crafting specialized aerospace parts, the benefits of this technology are manifold. It enhances operational efficiency, reduces the risk of tool breakage, accelerates production timelines, simplifies the tapping process, and ensures the adaptability to various materials. The Auto Self Reversing Tapping Head, enhanced by the functionality of a reversible tapping chuck, has become a cornerstone in modern manufacturing and machining practices. Its application is a testament to the ongoing evolution of machining technology, striving for higher precision, greater efficiency, and enhanced versatility. As industries continue to demand tighter tolerances and faster turnaround times, the role of advanced tapping solutions like this becomes increasingly critical, underscoring their value in achieving excellence in manufacturing.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Auto Self Reversible Tapping Chuck Set

1 x Protective Case

Please contact us for further information. To assist you more effectively, Kindly provide the following details:

● Specific product models and the approximate quantities you require.

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.