HSS DP Involute Iav Cutters Nrog PA20 Thiab PA14-1/2

DP Involute Iav Cutters

● #8 cutter rau 12 & 13 Txiav iav

● #7 cutter rau 14-16 Txiav iav

● #6 cutter rau 17-20 Txiav iav

● #5 cutter rau 21-25 Txiav iav

● #4 cutter rau 26-34 Txiav iav

● #3 cutter rau 35-54 Txiav iav

● #2 cutter rau 55-134 Txiav iav

● #1 cutter rau 135 rau Rack Cuts gears

PA 20 Type

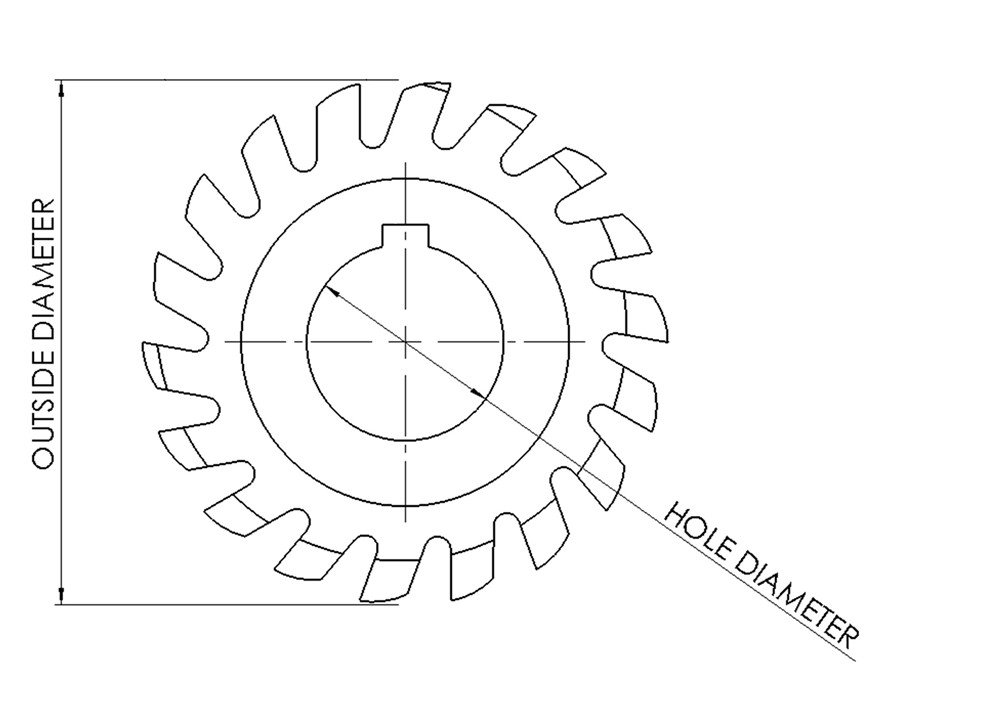

| DP | CUTTER DIA. | HLO DIA. | 8pcs / thawv |

| 4 | 3-5/8 | 1-1/4 | 660-7754 Ib |

| 5 | 3-3/4 | 1-1/4 | 660-7755 Ib |

| 6 | 3-1/2 | 1-1/4 | 660-7756 ib |

| 7 | 2-7/8 | 1 | 660-7757 Ib |

| 8 | 2-7/8 | 1 | 660-7758 Ib |

| 9 | 2-3/4 | 1 | 660-7759 Ib |

| 10 | 2-3/4 | 1 | 660-7760 ib |

| 12 | 2-5/8 | 1 | 660-7761 Ib |

| 14 | 2-1/2 | 1 | 660-7762 ib |

| 16 | 2-1/2 | 1 | 660-7763 ib |

| 18 | 2-3/8 | 1 | 660-7764 Ib |

| 20 | 2-3/8 | 1 | 660-7765 ib |

| 24 | 2-1/4 | 1 | 660-7766 ib |

| 48 | 1-3/4 | 7/8 | 660-7767 Ib |

PA14-1/2 Hom

| MODULE | CUTTER DIA. | HLO DIA. | 8pcs / thawv |

| 2 | 5-3/4 " | 1-1/2 " | 660-7768 ib |

| 2-1/2 | 5-3/4 | 1-1/2 | 660-7769 Ib |

| 3 | 5-1/4 | 1-1/4 | 660-7770 Ib |

| 4 | 4-1/4 | 1-1/4 | 660-7771 Ib |

| 5 | 3-5/8 | 1-1/4 | 660-7772 ib |

| 6 | 3-1/2 | 1-1/4 | 660-7773 ib |

| 7 | 2-7/8 | 1 | 660-7774 Ib |

| 8 | 2-7/8 | 1 | 660-7775 Ib |

| 9 | 2-3/4 | 1 | 660-7776 ib |

| 10 | 2-3/4 | 1 | 660-7777 Ib |

| 11 | 2-3/8 | 1 | 660-7778 Ib |

| 12 | 2-5/8 | 1 | 660-7779 Ib |

| 14 | 2-1/2 | 1 | 660-7780 Ib |

| 16 | 2-1/2 | 1 | 660-7781 Ib |

| 18 | 2-3/8 | 1 | 660-7782 ib |

| 20 | 2-3/8 | 1 | 660-7783 ib |

| 22 | 2 | 7/8 | 660-7784 Ib |

| 24 | 1-3/4 | 7/8 | 660-7785 Ib |

| 26 | 1-3/4 | 7/8 | 660-7786 ib |

| 28 | 1-3/4 | 7/8 | 660-7787 Ib |

| 30 | 1-3/4 | 7/8 | 660-7788 Ib |

| 32 | 2-1/4 | 1 | 660-7789 Ib |

| 48 | 1-3/4 | 7/8 | 660-7790 Ib |

Daim ntawv thov

Muaj nuj nqi rau Gear Cutter:

1. Gear Machining: Iav cutters yog siv los zeb cov profiles ntawm lub zog, kom ntseeg tau meej qhov ntev thiab cov duab. Qhov no suav nrog ntau hom iav xws li spur iav, helical iav, thiab iav iav.

2. Gear Truing: Thaum lub sij hawm tsim khoom, iav cutters kuj tau siv rau qhov tseeb lossis kho qhov chaw ntawm lub iav kom ua tau raws li cov qauv tsim.

3. Precision: Gear cutters xyuas kom meej tias cov iav ua tiav qhov siab ntawm qhov ntev thiab cov duab geometric, tseem ceeb heev rau kev ua haujlwm du thiab kev ua haujlwm ntawm cov kab ke.

Kev Ua Haujlwm Zoo: Siv cov iav cutters tuaj yeem ua tiav cov iav machining, txhim kho kev tsim khoom thiab txo cov nqi tsim khoom.

4. Versatility: Gear cutters yuav siv tsis tau tsuas yog rau machining hlau gears tab sis kuj rau kev ua cov iav ua los ntawm cov ntaub ntawv xws li yas thiab ntoo, muab ntau yam kev siv.

Kev siv thiab ceev faj rau Gear Cutter:

Kev Xaiv Cov Cutter: Xaiv cov iav cutter uas tsim nyog raws li hom thiab cov khoom siv ntawm lub iav yuav tsum tau machined, nrog rau qhov xav tau tshwj xeeb thiab kam rau ua.

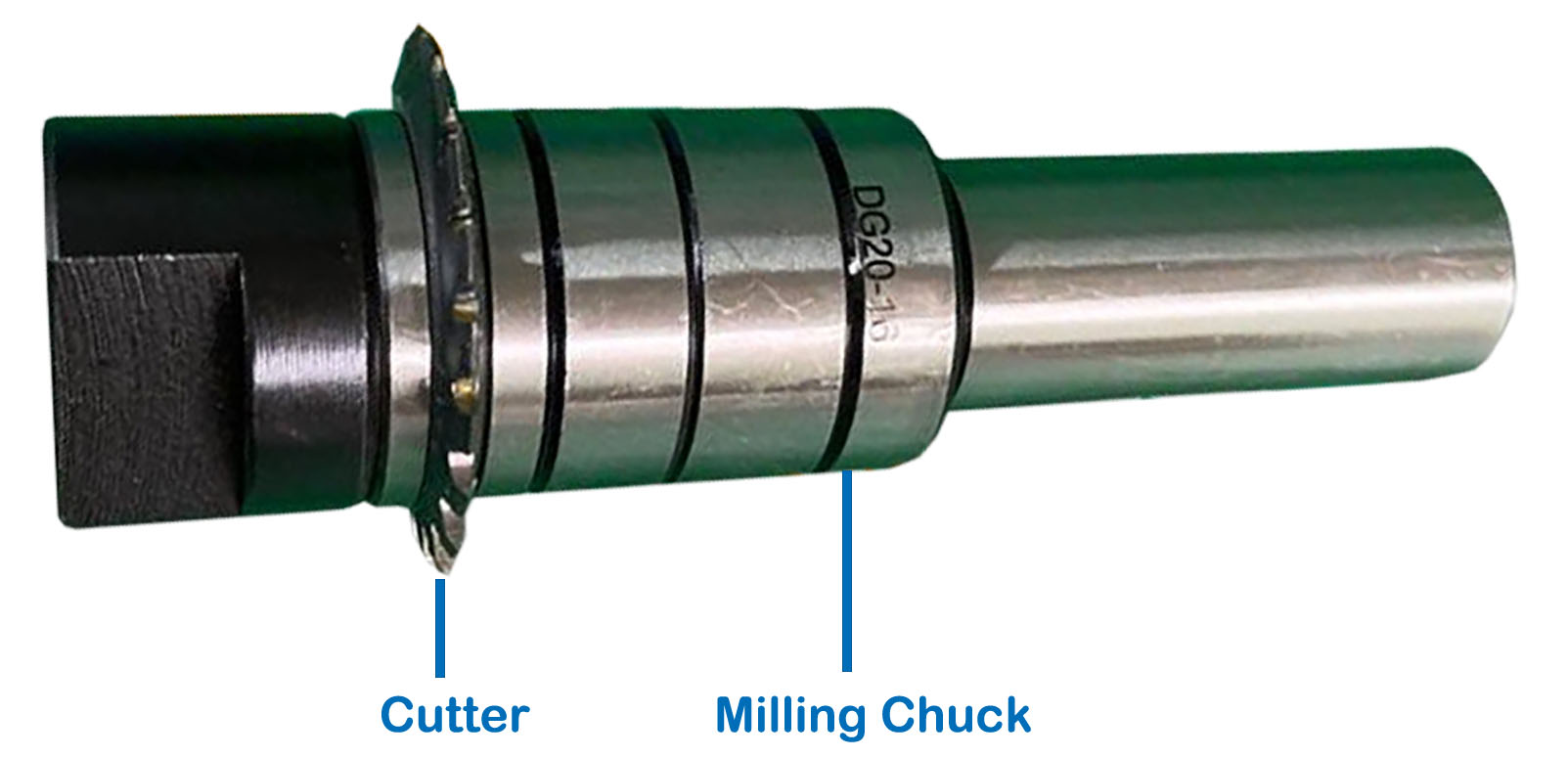

Kev teeb tsa: ruaj ntseg mount lub iav cutter ntawm lub tshuab milling spindle, kom ntseeg tau tias kev sib raug zoo thiab concentricity.

Workpiece Fixturing: ruaj ntseg clamp lub workpiece ntawm lub rooj tshuab milling, kom ruaj khov thiab qhov chaw zoo rau kev ua haujlwm raug.

Kev Txiav Txiav: Teem lub txiav tsis xws li ceev, pub tus nqi, thiab qhov tob ntawm kev txiav raws li cov khoom thiab qhov loj ntawm lub iav, nrog rau lub peev xwm ntawm lub tshuab milling.

Machining Txheej Txheem: Ua tib zoo ua cov txheej txheem milling, ua kom muaj kev sib tw thiab khov kho ntawm lub tshuab txiav milling hla lub workpiece nto kom ua tiav cov iav profile thiab qhov ntev.

Kev Siv Coolant: Nyob ntawm cov khoom siv ua tshuab, siv cov khoom ua kom txias lossis cov roj nplua nyeem kom tshem tawm cov cua sov thiab txhim kho cov nti khiav tawm, kom ntseeg tau tias kev ua haujlwm zoo dua thiab ua kom lub neej ntev.

Kev Nyab Xeeb Kev Nyab Xeeb: Ib txwm hnav cov iav kev nyab xeeb tsim nyog xws li tsom iav, hnab looj tes, thiab kev tiv thaiv pob ntseg kom tiv thaiv kev raug mob los ntawm ya ya, suab nrov, thiab lwm yam kev phom sij.

Kev tshuaj xyuas cov cuab yeej: tsis tu ncua xyuas lub iav cutter kom pom tias hnav, puas, lossis dullness. Hloov cov cutters hnav los yog puas tsuaj sai sai kom tswj tau qhov zoo ntawm machining thiab tiv thaiv kev sib tsoo.

Kev Kho Tshuab: Ua kom lub tshuab milling nyob rau hauv kev ua haujlwm zoo los ntawm kev ua haujlwm tsis tu ncua xws li tu, lubrication, thiab calibration, kom ntseeg tau tias kev ua haujlwm zoo thiab kev nyab xeeb.

Kev tuav cov cuab yeej: tuav cov iav cutters nrog kev saib xyuas kom tsis txhob poob los yog ua yuam kev, uas tuaj yeem ua rau puas tsuaj lossis raug mob. Siv cov txheej txheem nqa kom zoo thiab cov txheej txheem khaws cia kom muaj kev ncaj ncees ntawm cov cuab yeej.

Chip Management: Ua kom zoo tswj cov chips thiab swarf generated thaum lub sij hawm machining los tiv thaiv tsub zuj zuj thiab cuam tshuam nrog cov txheej txheem txiav los yog tshuab Cheebtsam.

Kev cob qhia tus neeg ua haujlwm: xyuas kom cov neeg ua haujlwm tau txais kev cob qhia txaus thiab paub txog kev ua haujlwm ntawm cov iav cutters, nrog rau cov txheej txheem kev nyab xeeb thiab cov txheej txheem machining kom raug.

Qhov zoo

Kev pabcuam zoo thiab ntseeg tau

Wayleading cuab yeej, koj ib-stop tsum rau tej cuab yeej, machinery accessories, ntsuas cov cuab yeej. Raws li lub tuam txhab kev lag luam sib xyaw ua ke, peb muaj kev txaus siab loj heev hauv peb Cov Kev Pabcuam Uas Muaj Peev Xwm thiab ntseeg tau, tsim kom tau raws li cov kev xav tau sib txawv ntawm peb cov neeg siv khoom. Nyem qhov no kom paub ntxiv

Zoo Zoo

Ntawm Cov cuab yeej Wayleading, peb txoj kev cog lus rau Kev Zoo Zoo muab peb sib cais ua ib qho kev quab yuam loj hauv kev lag luam. Raws li lub zog sib xyaw ua ke, peb muab ntau yam kev daws teeb meem kev lag luam, muab cov cuab yeej txiav zoo tshaj plaws rau koj, ntsuas cov cuab yeej meej, thiab cov cuab yeej siv tshuab txhim khu kev qha.NyemNtawm no Rau Ntau

Tus nqi sib tw

Txais tos rau Wayleading cuab yeej, koj ib-stop tsum rau tej cuab yeej, ntsuas cov cuab yeej, machinery accessories. Peb muaj kev txaus siab heev hauv kev muab Kev Sib Tw Tus Nqi Uas yog ib qho ntawm peb qhov zoo tshaj plaws.Nyem qhov no kom paub ntxiv

OEM, ODM, OBM

Ntawm Wayleading Tools, peb muaj kev txaus siab los muab kev pabcuam OEM (Cov Khoom Siv Tseem Ceeb), ODM (Original Tsim Chaw Tsim Tshuaj), thiab OBM (Own Brand Chaw Tsim Tshuaj), kev pabcuam rau koj cov kev xav tau tshwj xeeb thiab cov tswv yim.Nyem qhov no kom paub ntxiv

Ntau yam

Zoo siab txais tos rau Wayleading cuab yeej, koj all-in-ib lo lus uas peb rau cov kev lag luam kev daws teeb meem, qhov chaw peb tshwj xeeb hauv cov cuab yeej txiav, ntsuas ntsuas, thiab cov cuab yeej siv tshuab. Peb lub ntsiab kom zoo dua yog nyob rau hauv muab ib tug Extensive Variety ntawm cov khoom, tailored kom tau raws li ntau haiv neeg xav tau kev pab ntawm peb esteemed neeg.Nyem qhov no kom paub ntxiv

Cov khoom sib xws

Matched Cutter: DP iav Cutter, Spline Cutter

Sib tw Arbor: Milling Tshuab Arbor

Kev daws

Kev pab txhawb nqa:

Peb zoo siab los ua koj tus kws kho mob rau ER collet. Peb zoo siab los muab kev txhawb nqa rau koj. Txawm hais tias nws yog thaum lub sijhawm koj cov txheej txheem muag lossis koj cov neeg siv khoom siv, thaum tau txais koj cov lus nug, peb yuav teb koj cov lus nug tam sim. Peb cog lus tias yuav teb tsis pub dhau 24 teev ntawm qhov tseeb, muab kev daws teeb meem rau koj.Nyem qhov no kom paub ntxiv

Customized Services:

Peb txaus siab muab cov kev pabcuam customized rau koj rau ER collet. Peb tuaj yeem muab kev pabcuam OEM, tsim khoom raws li koj cov duab kos; OBM cov kev pabcuam, ua kom peb cov khoom lag luam nrog koj lub logo; thiab ODM kev pabcuam, hloov kho peb cov khoom raws li koj qhov kev xav tau. Txhua yam kev pabcuam customized koj xav tau, peb cog lus tias yuav muab cov kev pabcuam customized rau koj.Nyem qhov no kom paub ntxiv

Kev Pabcuam Kev cob qhia:

Txawm hais tias koj yog tus neeg yuav khoom ntawm peb cov khoom lossis tus neeg siv kawg, peb zoo siab tshaj los muab kev pabcuam kev cob qhia kom ntseeg tau tias koj siv cov khoom koj yuav los ntawm peb kom raug. Peb cov ntaub ntawv kev cob qhia tuaj hauv cov ntaub ntawv hluav taws xob, yeeb yaj kiab, thiab cov rooj sib tham hauv online, tso cai rau koj xaiv qhov kev xaiv yooj yim tshaj plaws. Los ntawm koj qhov kev thov rau kev cob qhia rau peb cov kev daws teeb meem kev cob qhia, peb cog lus tias yuav ua kom tiav tag nrho cov txheej txheem hauv 3 hnubNyem qhov no kom paub ntxiv

Kev pab cuam tom qab muag:

Peb cov khoom tuaj nrog 6 lub hlis tom qab kev muag khoom. Thaum lub sijhawm no, txhua yam teeb meem uas tsis txhob txwm ua yuav raug hloov lossis kho dawb. Peb muab kev pabcuam rau cov neeg siv khoom ib puag ncig, tuav cov lus nug lossis kev tsis txaus siab, ua kom koj muaj kev yuav khoom zoo.Nyem qhov no kom paub ntxiv

Solution Design:

Los ntawm kev muab koj cov khoom siv machining blueprints (lossis pab tsim 3D kos duab yog tias tsis muaj), cov khoom siv tshwj xeeb, thiab cov ntsiab lus siv tshuab siv, peb cov khoom lag luam yuav txiav cov lus pom zoo tshaj plaws rau cov cuab yeej txiav, cov cuab yeej siv kho tshuab, thiab ntsuas ntsuas, thiab tsim cov kev daws teeb meem machining. rau koj.Nyem qhov no kom paub ntxiv

Ntim

Ntim hauv ib lub thawv yas los ntawm lub hnab ntim cua sov. Tom qab ntawd ntim rau hauv ib lub thawv sab nraud. Nws tuaj yeem tiv thaiv zoo los ntawm xeb.

Kuj customized packing yog txais tos.

Automotive Iav Efficiency

DP Involute Iav Cutter yog ib qho cuab yeej tseem ceeb hauv kev tsim cov iav, tshwj xeeb tsim los tsim cov iav nrog qhov tseeb involute profiles. Cov cutters no, muaj nyob rau hauv ib tug ntau yam ntawm diametral pitch (DP) ntau thiab tsawg, cater rau ntau yam iav qhov ntev thiab specifications.

Hauv kev lag luam automotive, DP Involute Iav Cutters ua lub luag haujlwm tseem ceeb hauv kev tsim cov iav nyuaj rau kev sib kis thiab kev sib txawv. Lawv cov precision ua kom cov iav sib koom ua ke, ua rau muaj txiaj ntsig zoo rau kev ua haujlwm thiab kev ua haujlwm ntawm cov tsheb.

Aerospace iav Precision

Hauv kev tsim khoom hauv aerospace, cov cutters no yog qhov tseem ceeb rau kev tsim cov iav siab uas pom muaj nyob rau hauv cov tshuab dav hlau thiab cov cuab yeej tsaws iav. Lawv tsim lub zog muaj peev xwm ua rau muaj kev ua haujlwm siab thiab kev thauj khoom, ua tau raws li qhov xav tau nruj ntawm kev siv aerospace.

Muaj Machinery Durability

Rau cov tshuab hnyav thiab cov khoom siv hauv kev tsim khoom, DP Involute Iav Cutters yog siv los ua cov iav loj tsim nyog rau cranes, tsheb laij teb, thiab conveyor systems. Lub durability thiab meej ntawm cov cutters no yog qhov tseem ceeb rau lub neej ntev thiab kev cia siab ntawm cov tshuab hnyav hnyav.

Robotics Gear Accuracy

Nyob rau hauv robotics thiab automation, cov iav cutters yog ua hauj lwm los tsim me me, high-precision iav qhov tseem ceeb rau lub meej txav thiab tswj xav tau nyob rau hauv robotic systems.

Custom Gear Flexibility

Ntxiv mus, nyob rau hauv kev cai iav fabrication, DP Involute Gear Cutter muaj qhov yooj yim los tsim cov iav nrog cov cim tshwj xeeb lossis cov kev cai tshwj xeeb. Qhov kev hloov pauv no yog qhov tseem ceeb rau kev tsim cov iav kev cai rau cov tshuab tshwj xeeb lossis hloov cov khoom hauv cov khoom siv vintage.

DP Involute Gear Cutter qhov kev txawj ntse hauv kev tsim cov iav nrog cov ntsiab lus tsis sib xws rau ntau qhov chaw, suav nrog tsheb, aerospace, thiab cov tshuab ua lag luam, qhia txog nws lub luag haujlwm tseem ceeb hauv kev tsim khoom niaj hnub no. Nws muaj peev xwm ua kom haum cov iav sib txawv ntawm qhov ntau thiab tsawg thiab cov lus qhia tshwj xeeb ua rau nws yog ib qho cuab yeej tseem ceeb hauv cov txheej txheem tsim khoom.

Advantage Of Wayleading

• Kev Pabcuam Zoo thiab ntseeg tau;

• Zoo Zoo;

• Tus nqi sib tw;

• OEM, ODM, OBM;

• Muaj ntau yam

• Kev xa khoom sai & ntseeg tau

Cov ntsiab lus pob

1 x HSS DP Involute Iav Cutters

● Koj puas xav tau OEM, OBM, ODM lossis nruab nrab ntim rau koj cov khoom?

● Koj lub tuam txhab npe thiab cov ntaub ntawv tiv tauj kom tau txais cov lus teb sai thiab raug.

Ntxiv thiab, peb caw koj thov cov qauv rau kev kuaj zoo.