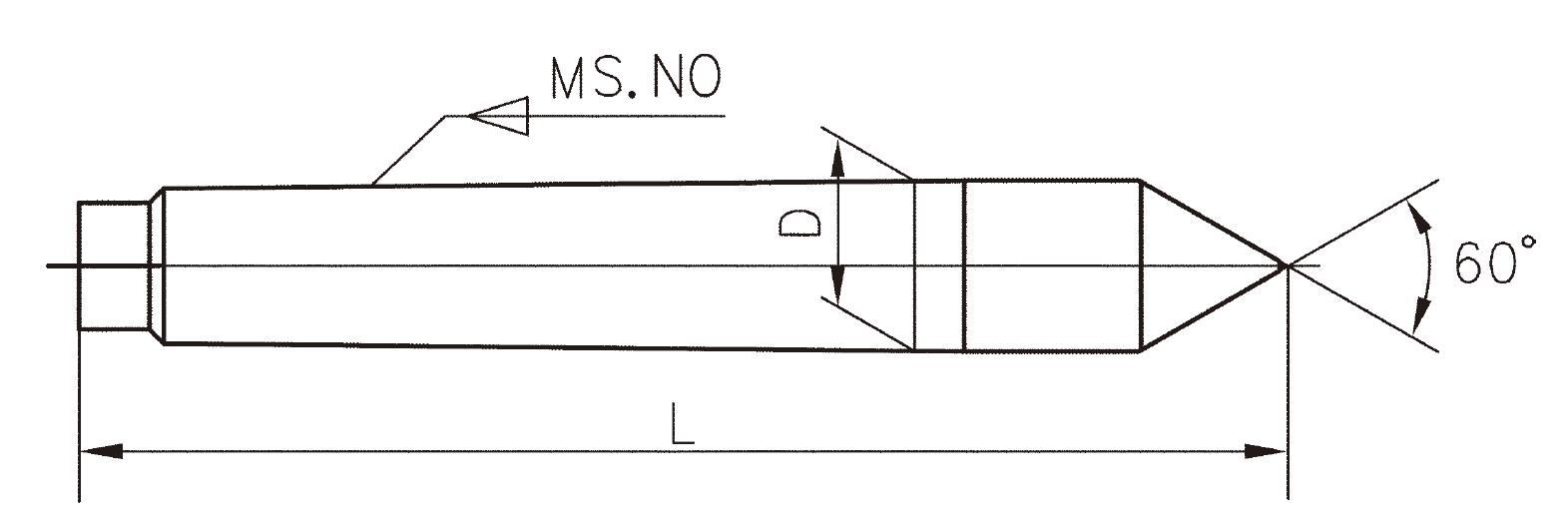

Dead Center For Morse Taper Shank

Dead Center

● Hardened and ground to the closest tolerence.

● HRC 45°

| Model | Ms. No. | D(mm) | L(mm) | Order No. |

| DG1 | MS1 | 12.065 | 80 | 660-8704 |

| DG2 | MS2 | 17.78 | 100 | 660-8705 |

| DG3 | MS3 | 23.825 | 125 | 660-8706 |

| DG4 | MS4 | 31.267 | 160 | 660-8707 |

| DG5 | MS5 | 44.399 | 200 | 660-8708 |

| DG6 | MS6 | 63.348 | 270 | 660-8709 |

| DG7 | MS7 | 83.061 | 360 | 660-8710 |

Precision in Metalworking

Precision in Metalworking

In metalworking, the Dead Center is vital for machining long and slender shafts. It supports one end of the workpiece, preventing it from bending or vibrating due to the cutting forces. This is crucial in maintaining the cylindrical accuracy and surface finish of the workpiece, especially in high-precision tasks such as the manufacturing of spindles, axles, or hydraulic components.

Woodworking Stability

Woodworking Stability

In woodworking, the Dead Center finds its use in turning operations for long wooden pieces, like table legs or spindle work. It ensures that these elongated pieces remain steady and centered during the turning process, which is essential for achieving a uniform and smooth finish. The Dead Center’s non-rotating characteristic is beneficial here, as it minimizes the risk of burning the wood due to friction.

Automotive Component Machining

Automotive Component Machining

In the automotive industry, the Dead Center is employed in the machining of critical components such as drive shafts, camshafts, and crankshafts. Its role in ensuring the alignment and stability of these components during machining is imperative to achieve the tight tolerances and surface finishes required in automotive parts.

Machinery Maintenance and Repair

Machinery Maintenance and Repair

Moreover, the Dead Center is also used in the maintenance and repair of machinery. In situations where precision alignment is needed for re-machining or refurbishing parts, the Dead Center offers a reliable solution for holding the workpiece in a fixed position.

In summary, the Dead Center’s application in providing stability, precision alignment, and support for elongated and slender workpieces makes it an invaluable tool in various machining processes. Whether in metalworking, woodworking, automotive manufacturing, or machinery maintenance, its contribution to precision and quality is undeniable.

Advantage Of Wayleading

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

Package Content

1 x Dead Center

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.