Boring Head Shank For Boring Head With Industrial Type

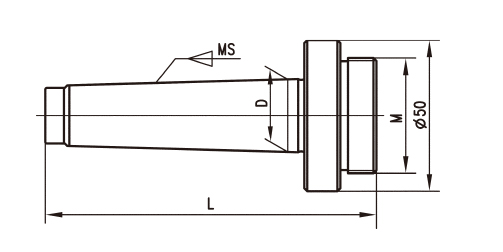

Specification

● All of the shank is suitable for F1.

● Shank Type: MT, NT, R8, Straight, BT, CAT, and SK

Back thread for MT draw bar:

MT2:M10X1.5, 3/8"-16

MT3:M12X1.75, 1/2"-13

MT4:M16X2.0, 5/8"-11

MT5:M20X2.5, 3/4"-10

MT6:M24X3.0, 1"-8

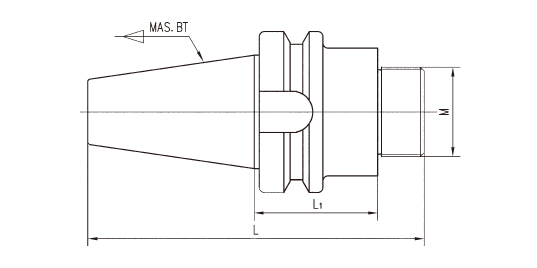

Back thread for BT draw bar:

BT40: M16X2.0

Back thread for NT draw bar:

NT40:M16X*2.0, 5/8"-11

Back thread for CAT draw bar:

CAT40: 5/8"-11

Back thread for R8 draw bar:

7/16"-20

Back thread for SK draw bar:

SK40: 5/8"-11

| Size | Shank | L | Order No. |

| F1-MT2 | MT2 with Tang | 93 | 660-8642 |

| F1-MT2 | MT2 draw bar | 108 | 660-8643 |

| F1-MT3 | MT3 with Tang | 110 | 660-8644 |

| F1-MT3 | MT3 draw bar | 128 | 660-8645 |

| F1-MT4 | MT4 with Tang | 133 | 660-8646 |

| F1-MT4 | MT4 draw bar | 154 | 660-8647 |

| F1-MT5 | MT5 with Tang | 160 | 660-8648 |

| F1-MT5 | MT5 draw bar | 186 | 660-8649 |

| F1-MT6 | MT6 with Tang | 214 | 660-8650 |

| F1-MT6 | MT6 draw bar | 248 | 660-8651 |

| F1-R8 | R8 | 132.5 | 660-8652 |

| F1-NT30 | NT30 | 102 | 660-8653 |

| F1-NT40 | NT40 | 135 | 660-8654 |

| F1-NT50 | NT50 | 168 | 660-8655 |

| F1-5/8" | 5/8" Straight | 97 | 660-8656 |

| F1-3/4" | 3/4" Straight | 112 | 660-8657 |

| F1-7/8" | 7/8" Straight | 127 | 660-8658 |

| F1-1" | 1“ Straight | 137 | 660-8659 |

| F1-(1-1/4") | 1-1/4" Straight | 167 | 660-8660 |

| F1-(1-1/2") | 1-1/2" Straight | 197 | 660-8661 |

| F1-(1-3/4") | 1-3/4" Straight | 227 | 660-8662 |

| BT40 | BT40 | 122.4 | 660-8663 |

| SK40 | SK40 | 120.4 | 660-8664 |

| CAT40 | CAT40 | 130 | 660-8665 |

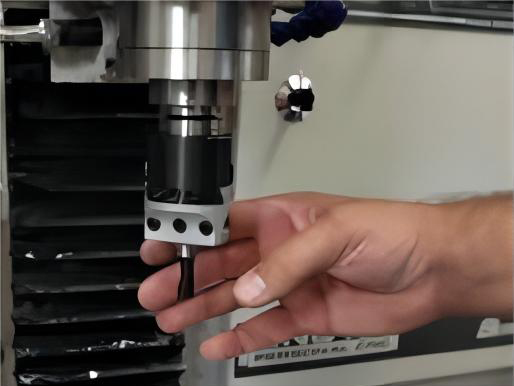

Shank Variety and Integration

The Boring Head Shank is a vital accessory for the F1 Rough Boring Head, designed to seamlessly integrate the boring head with various machine tools. It comes in multiple shank types, including MT (Morse Taper), NT (NMTB Taper), R8, Straight, BT, CAT, and SK, catering to a diverse range of machining setups. Each type is precisely engineered to ensure optimal alignment and rigidity, which are critical for high-precision boring operations.

MT and NT for General Machining

The MT and NT shanks, with their tapered profiles, are excellent for general and heavy-duty machining, providing a tight and secure fit in the spindle, thus reducing vibration and enhancing accuracy.

R8 Shank Versatility

The R8 shank, commonly used in milling machines, is ideal for tool rooms and job shops, offering versatility and ease of use.

Straight Shank Adaptability

Straight shanks are adaptable for various applications, allowing for a straightforward and reliable setup.

BT and CAT for CNC Precision

The BT and CAT shanks are predominantly used in CNC machining centers. They are renowned for their high accuracy and stability, making them suitable for complex and precision-demanding tasks. These shanks ensure minimal tool deflection, which is vital for maintaining dimensional accuracy in CNC operations.

SK Shank for High-Speed Machining

The SK shank stands out for its excellent clamping force, making it a preferred choice for high-speed machining. Its robust design minimizes tool slippage and maintains precision even under high rotational speeds, which is crucial for tasks requiring a high degree of accuracy and efficiency.

Durability and Longevity

In addition to their specific applications, these shanks are designed for durability and long-term use. Their construction from high-quality materials ensures that they can withstand the stresses of various machining processes, from rough boring in heavy industrial applications to precision engineering.

Enhanced Versatility in Machining

The variety of shanks available for the F1 Rough Boring Head enhances its versatility, making it a crucial component in different machining contexts. Whether it’s in a high-volume production environment, a custom fabrication workshop, or an educational setting, the appropriate shank type can significantly impact the efficiency, accuracy, and outcome of the machining process.

Advantage Of Wayleading

• Efficient and Reliable Service;

• Good Quality;

• Competitive Pricing;

• OEM, ODM, OBM;

• Extensive Variety

• Fast & Reliable Delivery

Package Content

1 x Boring Head Shank

1 x Protective Case

● Do you require OEM, OBM, ODM or neutral packing for your products?

● Your company name and contact information for prompt and accurate feedback.

Additional, we invite you to request samples for quality testing.